ERP, BIM, and Industrie 4.0 in precast concrete production

Developments that have already led to new standards in highly automated industrial sectors, such as the automotive industry, are now entering production plants for precast concrete elements. Terms such as Industry 4.0 and BIM integration are catchwords that are widely used in headlines involving the digital transformation. A great number and variety of industrial sectors have demonstrated this transformation and now apply hardware and software components that have extensively automated fundamentally standardized and, by the same token, highly flexible production processes. The challenge for all companies involved lies in the intelligent application of the technology now available to them.

Automation has now been increasingly implemented in production of precast concrete members as well. The use of automation processes that have been specifically directed toward individual steps of work often leads to new challenges for downstream production tasks. The fact that this challenge occurs in relation to specific order execution, or also on a cross-company basis, has become evident in more and more frequent demand for BIM integration. The application of advanced software solutions, adapted to the respective industries concerned, has become indispensable towards successfully achieving effective inter-coordination of production actions, schedules, and many more such requirements.

Internationally, BIM planning processes are primarily carried out with Revit from Autodesk. This signifies that the selected application will be ideally based on Revit, or that it should at least be compatible with Revit.

To meet the trend toward BIM, Idat with its RevitPrecastLink software has already created a solution that enables the planning of precast concrete members with information directly from the Revit building model. The entire model, or parts thereof, is transferred to the proven CCAD program from Idat via an especially adapted and configurable interface. There, the entire planning of the precast parts takes place – with reinforcement, production plans, installation plans, and with control of the production machines via the CAD/CAM interface. After completion of planning in CCAD, the manufactured precast members are returned via RevitPrecastLink to the Revit model, where they are once again available to the BIM process.

All-in-one sector solution

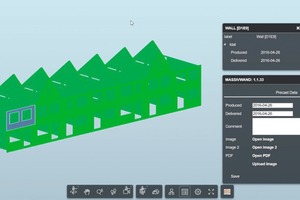

With its ERP solution especially adapted to the precast concrete industry, Idat for the first time presents a system in which all processes are digitally integrated – and in which all processes can be carried out in accordance with BIM stipulations. Idat-ERP contains all process-relevant data from one central model and also provides information once again in this model – which means that interface adaptation is no longer necessary. A direct link to the Revit building model is likewise integrated.

Idat-ERP encompasses all relevant functions for the control and monitoring of processes in a precast production plant: administration of customer data and order administration (CRM), rough and precise planning, calculation, production and capacity planning, materials management, warehousing management, order automation, logistics and assembly, financial accounting, as well as controlling and business intelligence.

The program is based on web services and is therefore flexible, location-independent, and capable of use by mobile devices. As a result of direct communication with the BIM central model, all required information is available: e.g., delivery scheduling, material lists, and data on the entire process if requested.

During upcoming years, the precast concrete sector will face major changes leading to digital technologies and services in the internet. Online services have already been frequently used – for example, in structuraldesign for buildings – without the requirement to install a particular program. Autodesk is a pioneer in the provision of such services, and the company Idat, as industrial partner of Autodesk, will further develop and adapt these technologies especially for the precast concrete industry.

Upon request, the Idat-ERP system will also be available as a complete cloud application, as a result of the intention of this company, located in Darmstadt, Germany, to provide the latest digital innovations in the precast concrete sector.