Energy-efficient heating system integrated in the reinforcement as precast carbon concrete element

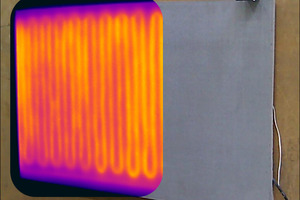

At present, about 70 % of space heating for private households are provided by fossil energy sources. The projected transition for using renewable energies exclusively leads to the fact that fewer and fewer power plants and combustion plants will be available in the future. Therefore, the development of innovative technologies for heat generation from electrical energy is mandatory. Heating elements made of thin-walled carbon-reinforced concrete provide a promising possibility here, because they allow the implementation of curved shapes and efficient functionality in combination with durability and cost effectiveness. The heating function in such a carbon-reinforced concrete element is realized in a non-impregnated, meander-shaped carbon fiber roving positioned on a glass-fiber grid (GFG). The carbon fiber allows for fast heating-up to the target temperature due to its high electrical conductivity and the negative temperature coefficient (thermistor), because the power input increases as temperature rises. Therefore, the heating-up time of a carbon-reinforced concrete slab to 90 °C amounts to about 30 min., whereas it amounts to about 90 min. for an electrical marble heating with the same area output. Due to the high heat storage capacity of concrete, the heating element remains warm for a long time after switch-off. In respect of the four-point bending tensile strength of the slabs, the GFG effects a strength increase by 57 % compared to non-reinforced concrete.

The practical implementation of this carbon-based concrete heating system is associated with numerous challenges. The concrete properties, for example, have to be designed purposefully, possibilities for later fastening have to be provided and energy supply, control and performance of the systems must be designed accordingly and specified. The manufacturer has to ensure the exact positioning of the integrated elements and the use of resource-conserving casting and formwork technologies.