Environmentally friendly sewer construction measure at 30-m depth

The public utilities company Stadtwerke Essen in Germany already began with renewal of the Wolfsbachtal sewer system in the summer of 2018. By now, most of the comprehensive construction measure has been implemented and is expected to be fully completed in late summer of 2021. The sewer was re-laid over a length of 2.7 km and replaces its predecessor from 1940.

The sewer runs parallel to the Wolfsbach, a river almost 4 km long that flows through the Essen district of Bredeney and empties into the Ruhr River. The dimensions of the new sewer pipes were based on a significantly larger volume, in some cases more than double the size, in order to be optimally prepared to deal with future heavy rain and to prevent sewage from flowing into the Wolfsbach. Following this rehabilitation measure, clean river water can now flow into the Ruhr River.

Berding Beton delivered 580 jacking pipes

In the planning stage of the construction measure – with the official name Wolfsbach Valley collector – comprehensive preparatory measures were necessary. An important concern was to keep interference with nature in the Wolfsbach Valley to a minimum and to protect the native flora and fauna found there as best as possible. This is primarily because nearly the entire construction site lies in a nature preserve. Accordingly, among the measures taken in addition to the sewer construction was the erection of an amphibian protection fence at the construction site. In the planning stage, a landscape conservation plan had been worked out, as well as an ecological forest monitoring program, which was decided on over the entire construction time. In addition, it was decided to install the greater part of the sewer pipes, around 2,000 m, underground by means of pipe jacking. Only 700 m were laid by the open-cut method. Among the advantages of the jacking method is that construction pits are required only in specific places, greatly reducing the environmental impact. But tunnel driving is also an interesting and attractive alternative from an economic point of view, because innovative pipe technology can significantly shorten the construction time.

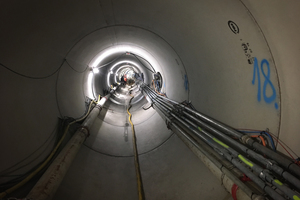

Jacking work started from the main jacking pit of around 23 m diameter, from which sewers of DN 1200, DN 1600 and DN 2600 diameter were installed in different directions. The triple jacking pit was for practical reasons expanded to form a rainwater retention basin. In preparing for the comprehensive rehabilitation measures, the narrow forest paths had to be temporarily and sufficiently stabilized so that they could withstand the heavy loads imposed by construction vehicles. Because 580 pipe elements with a total weight of over 10,000 tons were alone transported to the construction site in the Wolfsbach Valley.

Total weight over 10,000 tons

Berding Beton was commissioned to deliver the desired jacking pipes. The company, which is specialized in offering project-specific product solutions for demanding special civil engineering construction measures, profits here from its nearly 60 years of experience in the pipe-jacking sector. Accordingly, no standard products were delivered for this construction project. Instead, the reinforced-concrete pipes were manufactured individually to the wishes and technical specifications of the client. All jacking pipes were manufactured in the Berding Beton Schermbeck concrete plant, using state-of-the-art production methods and equipment, thus ensuring adherence to the specified quality level criteria on a high level.

The jacking piles that were left in the formwork for hardening ensure reliable processing of high-performance concretes with their known advantages as well as low tolerances –which are among the essential prerequisites for mastering jacking over long distances. The high number of 580 jacking pipes to be delivered required good planning with sufficient production lead time and high production output. Berding Beton satisfied this demand with its well-known reliability in work for its customers. The company Sonntag Baugesellschaft mbH & Co. KG was awarded contracts for expert execution of the works, with Chief Site Manager Heiko Andres having general responsibility for this demanding large-scale project.

Rainwater retention sewer 860 m long

For the 860-m rainwater retention sewer extending from the main jacking pit and continuing to the south, Berding Beton delivered 260 jacking pipes: each with an inside diameter of 2,600 mm, an outer diameter of 3,100 mm and an effective length of 4 m. The individual weight of a jacking pipe is 28 tons. Two pipe runs were laid toward the north: in one, 180 reinforced-concrete pipes with an inner diameter of 1,600 mm and a weight of around 9 tons were installed over a length of 540 m. In the other run, it was 110 reinforced-concrete pipes with 1,200-mm diameter. The delivery scope further included 30 precast manholes (DN 1000 to DN 2000) and 30 in-situ concrete structures. One of these was the rainwater retention basin, installed after completion of the jacking work with an impoundment volume of approx. 6,000 m3, a diameter of 21 m and a height of around 25 m at the initial triple jacking pit. Following completion of all works and after commissioning the new sewer, a no-longer needed rain overflow basin of the Ruhrverband – an operating water management company – was shut down. The now available field of around 1,300 m² was returned to nature so that a forest could grow there once again.

For this mammoth project, not only the pipe dimensions and the jacking work at a depth of 30 m posed a challenge. Local difficulties had to be overcome as well, such as the rocky soil conditions encountered with extreme values of the physical rock parameters. That jacking in the face of these marginally acceptable surrounding conditions could nevertheless be successfully mastered, was possible with the work of the experiencedteam from the Sonntag company. Achieving this outstanding performance, however, is also evidence that the apparent limits of trenchless pipelaying can be gradually overcome with the support of experienced staff, continuously improved systems and engineering as well as outstanding construction products.

After completion of the jacking work, all participants were very satisfied with the result of the good collaboration between Stadtwerke Essen as the client, the company Sonntag and Berding Beton. Jointly they professionally mastered all challenges and optimally implemented the construction project.