Facing the future with textile-reinforced concrete

Non-corrosive concrete reinforcement made of carbon and glass fibers provide for new design possibilities, increasing the efficiency in concrete construction. The Solidian company based in Albstadt, Baden-Württemberg, one of the leading institutions of textile research and technology in Germany, has substantially contributed to the development of this technology.

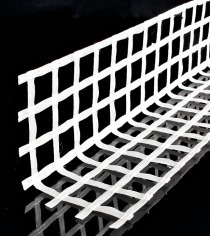

Since 2013, Solidian has been producing and distributing reinforcement products for a growing number of customers who have recognized the corrosion-free, lightweight and in any shape available alternative to reinforced concrete as a future technology. The plane or shaped reinforcement grids consisting of alkali-resistant (AR) glass fibers or carbon, which are hardened by a special impregnation, clearly outclass the conventional steel reinforcement in terms of efficiency and function.

Textile-reinforced concrete allows for thin and lightweight building components, as minimized concrete covers of 10 up to 15 mm are possible. Textile reinforcements, moreover, feature ultimate tensile stresses up to over 3,000 N/mm². There are significant savings in terms of the material input as well as in handling and transportation. In the long run, there are sustainable economic effects too: high costs for maintenance and refurbishment of rotten bridges will no longer incur. At present, manufacturers of precast concrete elements above all benefit from using Solidian products, for example, for façade elements, in garden and landscape architecture or in bridge construction. When it comes to the refurbishment of reinforced-concrete components or concrete components impermeable to water, the use of textile-reinforced concrete can also have economic benefits.