First HS-Alu-Premium Rack delivered to Saudi Arabia

The concrete block industry sees an enormous technological progress. On the one hand, this is characterized by advancing automation and high-tech machinery and, on the other hand, by new innovative products provided by the concrete block manufacturers. HS Anlagentechnik has kept in step with this advancement - HS-Alu-Premium, the aluminum version of the curing chambers, is an impressive evidence of this.

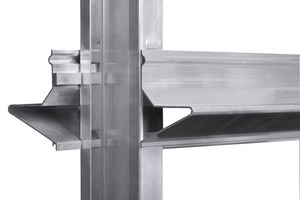

In the course of the construction of a new production facility of the Ahmed Ali Madkhali Factory at the location in Jizan in the south of Saudi Arabia, the company decided in favor of high-quality plant equipment including this innovative curing chamber system. Apart from the HS snap-in connection, the customer was in particular convinced by the advantages of the material aluminum. It is an all-purpose material with persuasive properties being synonymous with functional, durable and reliable products. Its very low weight along with its high strength and rigidity as well as the very high resistance to corrosion should be emphasized too. A Masa XL 9.2 is used as manufacturing plant. The company manufactures small-scale concrete elements in various shapes and sizes such as paving blocks or hollow blocks and shuttering blocks respectively. The HS-Alu-Premium curing chamber consists of 17 chambers and an additional pressure chamber for the Masa ventilation system. At a length of 19 m and an overall height of 8 m, it is possible to store 5,236 boards having a size of 1,400 x 1,300 mm on 22 racks in total. Each rack provides a capacity of 600 kg per board. In case of higher products being stored on every second rack a weight of 1,200 kg is easily possible. The standard design with an overall height of 8 m even does not constitute a problem for the HS-Alu-Premium curing chamber. The plant has been in operation since March 2012.

CONTACT

HS Anlagentechnik C.V.

Veldkuilstraat 53

6462 Kerkrade/Netherlands

+31 45 5671190

info@hsanlagentechnik.com http://hsanlagentechnik.com