ProCure for enhanced quality in concrete curing

“Klostermann are the best,” was the recent spontaneous reaction of an English production manager who had the opportunity of inspecting the production facilities in Coesfeld in the Munsterland region of North Rhine-Wesphalia. The good reputation of Klostermann is indeed not without good reason, since the blocks manufactured at this site satisfy the strictest requirements of aesthetics and technical standards. This is the reason why Klostermann decided on the ProCure concrete curing system from Rotho to meet and further enhance the company’s already high quality standards.

At the main Klostermann plant in Coesfeld, production takes place on two lines. On one line only high-quality cast stone blocks are manufactured, and high-quality concrete paving blocks are produced and finished by blasting and grinding on the second line. Production here includes the surfaces for which Kostermann enjoys a good degree of brand awareness on the market.

Constant product quality

A few years ago, the company took an unusual step in its finishing process to enable supply of the curing units in this production line with a sufficient number of concrete blocks for three-shift operation: something hitherto unconventional in curing technology. The big chambers were fitted inside with a curing rack executed with 19 passages and first-in / first-out operation. Six of these passages were converted into individual chambers and fitted with rolling shutter doors. The products in these chambers are hardened by vapor units for about 14 h at a temperature of 42 °C. In this configuration, bottlenecks occurred in this curing plant with increasing frequency. For this reason, Klostermann decided to heat the entire chamber system and to commission Rotho to design an appropriate concept.

Now, instead of only six chambers, the entire big-chamber system is fitted with an air circulation system. In addition, the new ProCure system for heating and humidifying will assure constant curing conditions the whole year round and, accordingly, constant quality and coloring of the blocks.

Advanced production opportunities

The main idea underlying this solution was that all products would be able to benefit from the controlled curing. The entire capacity of the curing rack for feeding the curing line is therefore available, instead of only six separate chambers. As a result, hardening can take place at significantly lower temperatures. This not only makes ecological sense, but appreciably reduces costs.

Initially, there was some skepticism at Klostermann as to whether hardening for 14 h could, in fact, be achieved at lower temperatures. But in a big chamber, the products are placed very quickly in a warm and moist environment, while conventional chamber versions must first be loaded and then heated. This costs time and energy, which can be saved as a result of the big-chamber solution.

Initial concerns soon gave way to enthusiasm, once Rotho had run tests on its mobile testing plant. After three test runs, it had become evident that the desired early strength after 14 h could be achieved in a big chamber – also at lower temperatures of between 35 und 38 °C. Based on these results, Klostermann decided on the Rotho ProCure concrete curing system.

ProCure concrete curing line for Klostermann

The mobile testing system from Rotho enables hardening tests at between 20 and 80 °C and at relative humidity of up to 100 %. The key feature of this plant is that tests can be run at the customer’s site with the original concrete mix, and running adjustments of the concrete block machine can be carried out. The results of the block strengths reached here can therefore be applied in practice.

The quality of the air circulation system during curing is crucial for the constant quality of the concrete products. The new air circulation system is essential for ensuring a balanced environment for the product and for effective introduction and distribution of heat and moisture in the curing chamber. The air circulation system at Klostermann ventilates the curing rack transversely to the chambers, to enable efficient first-in / first-out operation to best advantage. Six axial fans are installed for this purpose at approximately the middle of the 19 rack passages – for achieving the required air exchange factor, referenced to the volume of the curing rack.

Climate monitoring via RothoControl System

The moisture-controlled exhaust-air fans installed to support the air circulation system ensure that the relative humdity in the three zones in the curing rack does not exceed the required value of, for example, 90 %. The additional ceiling fans above the finger cars further ensure effective air circulation. System installation during the shutdown period in winter took place smoothly. The six chambers, including the rails, were dismantled within a very short time and replaced with new rack passages. The pipelines and the fans as well as the heating and humdifier stations were installed in parallel. The fully-functional plant was ready for operation prior to the scheduled commissioning date, at the beginning of February 2017.

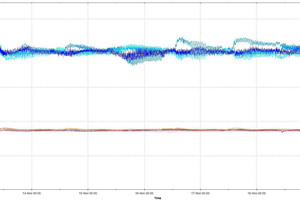

The plant is monitored by the RothoControl System developed by Rotho. The PC-based system enables optimal overview of the plant. All conditions of the ProCure System – for example, hot-air generation, humidifyers, fans, as well as all temperatures – are displayed on the overview screen. In addition, the progression of conditions in the curing environment is displayed by a system comprising a total of six moisture and temperature sensors. The display periods can be varied between one day and one year. The values determined are displayed in real time and as unsmoothed and individual values. The system does not display an imprecise averaging display. Another feature is the curing climate, which can be specified by using a program editor for each of the seven days of the week. In this way it is possible, for example, to reduce the humidity on a Sunday to save costs.

Hardness test ProCure System

Upon completion of the initial startup procedure, the sum total of the process- and control-engineering options offered by the Rotho Air Circulation and ProCure System revealed significant positive effects. Color variation and primary efflorescence, for example, are reduced to a minimum. The controlled environment during hardening effectively satisfies the requirement for constant product quality on the curing side.

The performance of the ProCure System became clear once again when Russian customers visited the plant. At the pallet discharge station of the chamber, concrete plant foreman Jürgen Fraune placed a concrete block 16 cm thick and weighing more than 50 kg on one side and caused it to tip over. The concrete block crashed with its full weight back onto the pallet and remained without any damage after only 12 h of hardening – which clearly impressed the visitors. Many visits to the company Klostermann have already now been followed by orders for the ProCure Systems.