From concrete residues to finished Lego blocks

Disposing of or land-filling concrete residues is expensive and wastes valuable resources. One of the low-cost options for reusing this concrete is to proc-ess it to concrete blocks suitable for a wide variety of structures, including walls, retaining elements or bulk-material boxes. Betonblock/Legoblock BV, a company based in Stompeto-ren, Netherlands, offers concrete block molds developed specifically for this purpose.

These molds are produced at the company’s own factory. They are made from high-quality, low-alloy structural steel that is exceedingly durable thanks to its powder coating. This system has been continuously improved ever since the first generation of concrete block molds was launched 20 years ago, and its popularity continues to increase – as proven by more than 3,000 customers in 35 countries across the world.

Production and use of concrete blocks

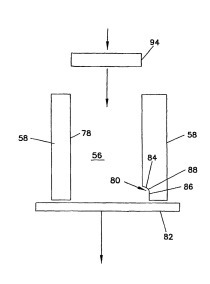

Release agent is applied to the bottom and side walls of the concrete block mold, which requires only a smooth and flat base, such as a 20 mm thick steel plate. Fresh concrete is cast into the mold and compacted for a short period, followed by smoothing of its surface. After one day of curing and cleaning of the casting mold, the mold is easily loosened using a key opener and made available for producing the next concrete block. A concrete block clamp is used to place the freshly demolded “Lego block”, which still lies on one of its sides, on the so-called rotator, which moves the block into an upright position.

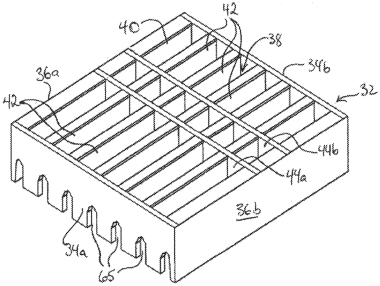

The concrete block’s design includes nubs at the top and cutouts at the bottom as well as a high own weight, which enables almost unlimited design freedom in a mortar-free, stackable construction system. Modifications and extensions are possible at any time without adversely affecting structural stability. In actual practice, concrete blocks are often used for bulk-material boxes, factory buildings, walls, fences and counterweights, but also in infrastructure and (road) construction projects. These stackable blocks are also suitable for constructing warehouses and other service buildings.

Various mold designs and dimensions

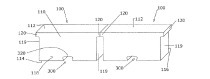

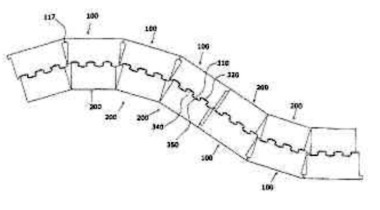

Concrete block molds are available in various shapes and dimensions: the quality of the concrete and the size and weight of the cast concrete block are determining factors for the intended use. Besides the standard block mold, the use of partial walls enables production of half or quarter concrete blocks, which are indispensable for erecting walls in a “Lego” design. A variable corner block mold was developed for building corners from 90° to 180°. Furthermore, special molds for stairs and oblique elements and a custom roof model mold are available. This 45° pitched roof model is placed on the top side of a wall.

Form liners provide additional options for various surface finishes and structures with greater aesthetic appeal.

Concrete slab production as an additional line of business

Particularly in the Netherlands, concrete slabs are predominantly used as large paving elements at industrial estates. Compared to small pavers, these large-format concrete slabs are installed – or removed, if required – very easily and quickly and thus well-suited to heavy goods vehicle and forklift traffic, parking lots and many other purposes. Even high point loads and extreme weather conditions will not pose any problems. If, however, slabs subside due to ground instability, they can be easily removed and replaced, unlike cast asphalt pavements.

Betonblock/Legoblock BV also offers a slab mold specifically designed for this type of use. Another benefit of these large slabs is that they allow easy access to the ground, for instance when having to perform work on power lines and other building services.