Gaining space and saving heat thanks to modern reinforcement technology

The “Neue Glacis Bastion” building complex in the center of Neu-Ulm is part of the urban redevelopment of the area west of Caponniere IV between the train station and Glacis Park. The developer of the residential and commercial object designed with a view to sustainability under ecological and energetic aspects is Eberhardt Immobi-lienbau GmbH based in Ulm; Höfle & Wohlrab Bau GmbH (HWB) is in charge of the construction work. The up to eight storeys house high-quality flats, offices, doctor‘s practices, restaurants, and an underground garage with 140 parking spaces. Punching shear reinforcements and brickwork support brackets by Berlin-based Jordahl GmbH make it possible to realize the modern flat-slab constructions and especially load-carrying foundations, as well as the energy-efficient installation of exposed-concrete elements for the design of the façade.

Today, high rooms, flat ceilings, curtain walls and clear lines are typical for the style of modern multi-functional buildings. The “Neue Glacis Bastion” project by Ulm-based Architects office Braunger Wörtz shows these characteristics. Thanks to innovative reinforcement and fastening technologies, it was possible to realize this construction proj-ect saving both costs and time.

90 percent more load-bearing capacity

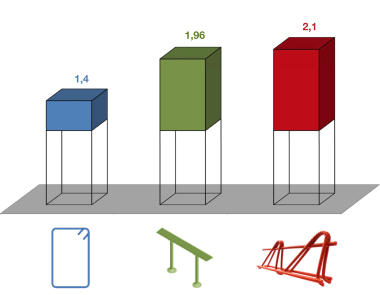

The plans for the building project included ceilings with low thickness. In order to prevent the slender supports from punching through the slabs, around 2,400 Jordahl punching shear reinforcements JDA were installed above the supports in the reinforcement of the ceiling formwork. This way, it was possible to realize flat-slab constructions without supporting beams as well as particularly load-carrying foundations. Punching shear reinforcements by Jordahl enable the transmission of high supporting forces with little formwork and reinforcement efforts. Specifically, this means that in comparison to flat slabs and foundations with conventional reinforcement technology, the punching shear resistance is increased by 90 percent when using Jordahl punching shear reinforcements. It was possible to do completely without intrusive supporting beams and thus make optimal use of the storeys heights. This also positively affects the construction costs.

Jordahl punching shear reinforcements JDA can be used in precast plants in precast slabs starting from a slab thickness of 18 cm or, as in the project in Neu-Ulm, in the site-placed concrete or reinforcement systems of the foundations and ceilings, respectively. Simple and quick installation is possible either from above or from below. The JDAs moreover result in a smooth soffit and can be used flexibly for all supporting positions and versions.

Radial arrangement around the perforation

During the construction phase, you could repeatedly observe how the punching shear reinforcements were installed in the horizontal reinforcement systems of the foundation and the ceilings: radially arranged around the places where dozens of slender supports grew upward together with the building. In this process, the installation of the JDAs took place quickly and without any problems, the parts arriving at the construction site just in time. A few skilled hands attached the punching shear reinforcements to the horizontally installed wire mesh by means of pincers and wire. The exact positioning and alignment was done with the aid of the markings made beforehand by the foreman, based on the location marks defined by the planner of the supporting structure. For this, the planners used a free software tool supplied by Jordahl.

Jordahl punching shear reinforcements JDA are available in various standard versions. The company moreover also designs customer-specific and case-specific versions. All JDA reinforcements have the European Technical Approval ETA-13/0136 and the German Technical Approval (Z-15.1-214).

Brickwork support brackets with energy benefit

When looking for a suitable connection system for the elements of the façade, the architects and structural engineers of the “Neue Glacis Bastion” building complex also decided in favor of products by Jordahl. “Particularly the JVAeco+ brickwork support brackets, of which we needed about 1,500, convinced us,” site manager Richard Atzkern of the construction company, Höfle & Wohlrab Bau (HBW), explains. These brackets made of Lean Duplex stainless steel 1.4362 are very cost-effective and durable fastening elements that take up the weight of the brickwork and of the exposed concrete elements running around it and transmit it into the load bearing structures via the Jordahl anchor channels. Together with the load bearing structures, they form a double-layer construction with excellent properties in terms of building physics.

Due to the numerous ecological and energetic requirements on the building project, especially the thermal optimization of the brickwork support brackets JVAeco+ turned out to be a major advantage. During the development of the brackets, the designers made sure that they were constructed with the focus on the essential static tasks. This way, it was possible to reduce the ratio of materials with thermal conductivity to a minimum. This is why the JVAeco+ brackets also meet the energetic requirements of the EnEV with the standard values of DIN 4108 (thermal insulation et al.) and DIN 18599 (energetic evaluation).

Various technically approved versions

The Jordahl brickwork support brackets JVAeco+ are available in various technically approved versions and are always designed in such a way that it is possible to install them quickly and with simple compensation for tolerances. One advantage in this process is the combination with Jordahl anchor channels JTA and with Jordahl thermal collars JTM which support an additional reduction of heat losses in the air space.

Jordahl was closely involved in the overall logistics of the construction company. Richard Atzkern, who, as site manager at HBW, was in contact with the responsible persons at Jordahl in almost all construction phases, recalls the good cooperation: “We had a very competent partner in both the field service and the responsible project management at all times. Based on the installation plan supplied by us, they worked out a detailed position plan with parts lists which made the orientation on site perfect for us. The information exchange and the coordination were absolutely smooth. All orders were filled in good time.” Not least because of the good delivery and construction processes, the project will be finalized as planned by the end of 2017.