Heavy-duty fixings secure Swinoujscie Tunnel

on Poland’s Baltic Sea coast

Poland’s longest underwater tunnel to date, the Swinoujscie Tunnel, is currently under construction in the city of Swinoujscie, connecting the islands of Uznam and Wolin. Crossing under the river Świna, it is expected to strengthen the coastal region by improving its infrastructure connection with the rest of the country and the world. More than 50,000 heavy-duty chemical and steel fixings from Fischer were used to reinforce the tunnel. The expert in fixing solutions will support the construction project right up to its successful completion by providing product and service expertise.

The city of Swinoujscie is currently building the new Swinoujscie Tunnel to improve the transportation link between the islands of Uznam and Wolin and to connect the coastal region more closely with the rest of Poland and the world. Completion is scheduled for the end of 2022, and the tunnel is expected to be opened in 2023. An emergency tunnel is under construction parallel to the large two-lane tunnel, which has a diameter of 12 m. The road tunnel will extend over a total length of just under 1.8 km. It will cross under the river Świna, which connects the Szczecin Lagoon with the sea, and will run between the two districts of Swinoujscie located on the islands of Uznam and Wolin. It will be Poland’s longest underwater tunnel. The Swinoujscie Tunnel will also form a part of Poland’s S3 expressway, which will connect northern and southern Poland over a distance of 500 km and will run from the western part of the city of Swinoujscie on the island of Uznam to the town of Lubawka in Silesia on the Czech-Polish border.

Stabilizing the supporting structure of reinforced concrete

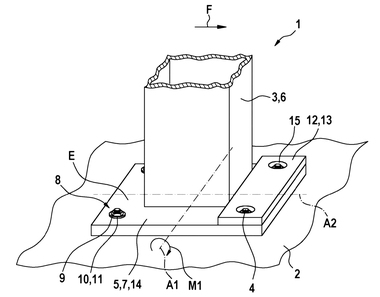

A tunnel boring machine (TBM) is used to drive around 1.5 kilometers of the Swinoujscie Tunnel. Further tunnel sections are completed using the top-down construction method, where excavation and construction take place below a roof slab cast on top of diaphragm walls. This construction method permits shoring of the excavation pit and continued use of the surface above the launch shafts on the islands of Uznam and Wolin. Heavy-duty fixings from Fischer are used to reinforce the tunnel after completion of the TBM work. The chemical fixing systems and steel anchors will stabilize the supporting structure of reinforced concrete. In the process, exceptionally high anchoring depths of up to 550 mm were realized using rods measuring M16 and M30 in diameter to connect the reinforced-concrete shells after completion of the TBM operation. The fixing solutions were also used to secure platforms and struts for the launch shafts.

“Our products met the requirements and standards of the project. Our heavy-duty fixings won out against competitor solutions and, in addition, we offered our clients a range of useful services,” says Oliwer Pietrzak, sales representative at Fischer’s Polish subsidiary in charge of the project. “We provided advice even prior to the start of construction. Our range of services included planning and designing the fixing solutions in collaboration with the engineering firm, which subsequently allowed us to fully exploit the potential inherent in our products. We also offered technical advice and support on the construction site.”

Injection mortar with a service life of 120 years

Fischer’s FIS EM Plus professional solution is the most widely used product. Combined with system components, the injection mortar can be relied on to permanently transfer high loads into the concrete even under extreme conditions such as earthquakes, water-filled boreholes or in the event of fire. Its two European Technical Approvals (ETAs) and special ICC approval for the US and Far Eastern countries include fixings in concrete as well as post-installed rebar connections. It has an ETA-certified service life of 100 years. Stuttgart-based engineering office IEA has even attested a service life of 120 years for anchorages using Fischer FIS EM Plus. It is the first injection mortar ever to be attributed this level of durability, which is an asset especially in infrastructure projects such as the Swinoujscie Tunnel that are designed for an extended period of use.

Fischer’s Superbond FIS SB mortar is also used in combination with system components. The fixing system uses silane technology and achieves an exceptionally high bond stress level for superior performance and safety, as certified by its ETAs for concrete and seismic stresses. The injection mortar permits variable anchoring depths, thus optimizing both installation time and the amount of material used. Mechanical anchoring solutions are also used, such as Fischer FBN II and FBZ bolt anchors as well as Fischer concrete screws.

In excess of 50,000 Fischer fixings have to date been used in the construction of the Swinoujscie Tunnel. And the expert in fixing solutions will continue to support the client by providing product and service expertise right up to the completion of the construction project, which is scheduled for the summer of 2023.