Henning Kortmann – technology pioneer and concrete specialist

Kortmann Beton GmbH & Co. KG was founded by Carl Kortmann in 1950; since that time, the company has been dealing in building materials for road construction, garden and landscape construction and civil engineering. The manufacture of concrete products began only a short time later. Henning Kortmann has been managing the company for five years now and has extensively modernized it.

Kortmann Beton GmbH & Co. KG, based in Schüttorf near the Dutch border, was founded by Carl Kortmann in 1950; since that time, the company has been dealing in building materials for road construction, garden and landscape construction and civil engineering. A few years later, the company started manufacturing concrete products, which allowed it to open up both domestic and international markets. From 1970, Karl Kortmann has been managing the company in the second generation; his sons, Matthias and Henning, joined him as part of the management team in 2014. This means that the company is now run by the family in the third generation.

Kortmann is a concrete producer manufacturing innovative product solutions to provide customers with environmental protection at the highest level. The production process itself is also sustainable as the company’s electricity and heat requirements are generated using renewable energies. Products failing to meet the company’s own high quality requirements are recycled in the raw materials cycle. Wastewater resulting from precast production is returned to production via a treatment process.

Kortmann offers vocational training in a wide variety of career profiles and provides long-term job security in order to ensure the continued existence and innovative strength of the company in the long term.

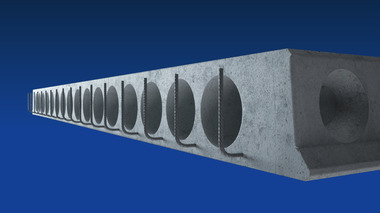

The broad portfolio of concrete products extends from terrace slabs via “green” pavers, decorative pavers and garden wall systems all the way to a comprehensive range of functional products including rectangular pavers, paving flags, curb systems, traffic management systems, interlocking and signaling pavers, lawn edging pavers, L, U and double-T blocks, rectangular retaining walls and speed bumps. State-of-the-art manufacturing technology is used in the process.

Third-generation entrepreneur

Henning Kortmann has been managing the company for five years and has modernized it extensively within a short period of time investing, for example, around 7 million euros in the renewal of production facilities and in the networking of manufacturing and sales data. “When I joined the company, there wasn‘t even a product catalogue, let alone real marketing. The machines were between 30 and 40 years old, and around 40,000 t of building rubble – overgrown with bushes – were lying around on the factory premises,” the Bachelor of Arts and concrete technologist remembers with a smile. “Since my father wanted to hand over the company to a suitable successor for health reasons, I was suddenly told: ‘Either you join the company – or we sell.’”

Today, the 32-year-old employs a staff of around 140 and generates annual sales of around 20 million euros. The change in generation alone would have been enough of a challenge, but Kortmann had set himself the goal of breathing new life into the company together with his young team and becoming one of the high-tech pioneers in the concrete block industry.

“Supported by my friend and authorized signatory, Julian Krümpel, I started out with a market analysis and visited other companies to find out which manufacturing technologies they used. Now precast producers from other German states and even from Dutch, Czech and Russian concrete plants are coming to us for information on digitization,” says Kortmann.

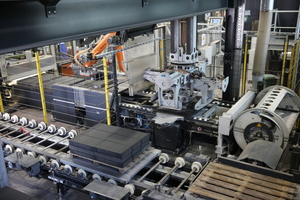

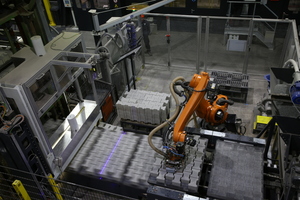

200,000 paving blocks and concrete slabs per day

Henning Kortmann is happy to show the visitors around his company in which the entire value chain of the processed concrete is digitally recorded. The highlight of the factory tour is the orange-colored Kuka robot, called “Wall-E” based on a science fiction film. Where a few years ago several employees had to manually discard the defective specimens from 200,000 paving blocks and concrete slabs produced per day, this is now performed by the electronic assistant. As soon as a 3D camera has identified a concreteblock as defective, the gripper arm of “Wall-E” is extended and lowered over the pallet. Using a vacuum suction cup, it removes the damaged block from the layer and deposits it in a separate location. The robot including inspection software was installed by the company Ibea from Hamburg.

The system is controlled via a software which analyzes production data such as the composition of the concrete mix including color, grading range, binders and water content. As a result of networking the data with the goods management system introduced in 2019, IT and production managers are able to identify where optimization is needed, be it in the machine settings of the block machine or in the time spent in the curing chamber.

“In the event of complaints, we can still trace the composition of the batch even after many years. And what’s more, offers can now be created four times faster than before,” Kortmann adds. “I’m not going to hide the fact that we did have some teething problems. If the position of the blocks changed only minimally on the old plants, which were not running very smoothly, the sensors of ‘Wall-E’ were unable to detect them. Either too few or too many defective specimens were removed, so that production was held up time and again. The ultimate remedy to the problem was to retrofit a smoother running conveyor system.”

New plant and know-how from KBH

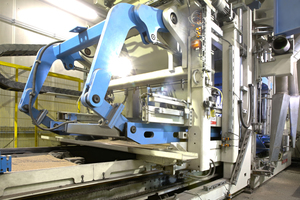

The new conveyor system was delivered by Upper Bavarian supplier KBH Baustoffwerke Gebhart & Söhne in conjunction with an extensive transfer of knowledge. Managing Director Hans Gebhart viewed himself not only as a mere plant supplier, but also as a mentor: “Being an ‘old hand’ in the industry at the age of 54, I felt a need not only to handle the actual order but also to provide active support to the dedicated ‘youngsters’ who were eager for knowledge. I was impressed by the short time in which Henning Kortmann and Julian Krümpel familiarized themselves with the subject, even though they were breaking new ground unknown to them at the time.”This technology and engineering drive enables sophisticated products to be manufactured in special designs and with creative coatings. The plants are capable of producing more than 200 different formats twice as fast as before. This allowed Kortmann to win the home improvement and DIY centers of Krefeld-based franchise chain “Bauen+Leben” as customers: terrace slabs and paving blocks produced in Schüttorf are now sold as private-label products in around 50 “Bauen+Leben” stores.

Environmentally sustainable production and recycling

Today, even the rubble dumps are put to use: for the past three years, they have been mixed with freshly demolished concrete to produce recycling material. The old material is crushed to different particle sizes which are then used in new paving blocks and concrete slabs.

All roofs of the corporate group are equipped with photovoltaic systems. A block-type thermal power plant produces electricity and heat for the factory, and the diesel truck on the company premises will be retrofitted with an electric motor in the near future. Henning Kortmann is particularly proud of the fact that some of his products offer environmental benefits. These include concrete slabs installed at filling stations and chemical plants to prevent fuels and chemicals from seeping into the ground. Precast elements from Kortmann are also used in the construction of transformer stations on the north-south power line or serve as foundations for electric car charging stations, thus supporting energy transition and climate protection.

Although sales in 2018 were weaker because production had to be interrupted for months due to the plant’s modification, the figures are now back on track. “In the first half of 2019, the company was set to achieve record results – with margins rising in all product areas,” Kortmann concludes. “We have now reached the point where our innovations generate added value. What I’d never have thought possible in my youth: in the meantime I’ve become a genuine died-in-the-wool concrete specialist.”