Highly automated reinforced solid panel production

CSR Hebel can look back on a long history. With over 25 years of experience, a focus on knowledge, innovation and high standards of production has enabled Hebel to stand out as a supplier of autoclaved aerated concrete (AAC). In fact, Hebel is Australia’s only manufacturer of high-performance AAC products for residential, commercial, civil and infrastructure applications. Recently the company invested in a new cage welding plant in order to meet expanding requirements for their business. Their current manufacturing plant was all manual with each process requiring several operators. The new line automated the entire process.

CSR Hebel: a wide-ranging portfolio with tradition

Hebel is the only Australian-made AAC on the market. The company can count on a highly experienced local technical and engineering support team. Hebel has developed a patented hoisting solution, making it much easier to install boundary and intertenancy walls in areas with limited access. The company has about 120 employees and offers innovative building solutions that are strong, versatile and sustainable. Hebel panels are high-performance products containing steel reinforcement for added strength with an anti-corrosion layer on the steel for maximum durability. CSR Hebel expanded to a second production facility, for which they hired Aircrete Europe, where they produce highly customized turn-key AAC.

AAC applications

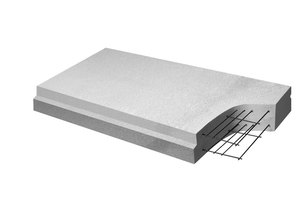

AAC is a solid yet lightweight building material widely used in construction throughout the world. In the AAC manufacturing process, water and readily available dry ingredients – sand, lime and cement – are mixed with an expansion agent to form a semi-liquid mix called slurry which is poured into a mold. If panels are being produced, then steel mesh reinforcement will be appropriately placed in the mold before the slurry pour. AAC is much lighter than traditional concrete, yet strong and solid with excellent thermal properties.

Convinced by reliability

The fact that the choice fell on the customized cage welding plant from Progress Maschinen & Automation, one of the companies of the Progress Group, was no accident. “The reason for our partnership with Progress is the reliability of the machines and services,” says Engineering and Reliability Manager Tim Grabham. “We felt Progress had expertise in mesh handling that we had not seen with any other supplier and this is what we needed for our new plant. Building growth has been very strong in both the low-rise housing and multi-residential market, and very strong in the high-rise apartment segments. We are currently experiencing a slowdown in all segments due to Covid-19.”

The entire machine was designed in collaboration with Progress engineers to meet the requirements of the new plant. The new cage welding plant is located near Sydney in Australia and was built for the cost-effective manufacture of bespoke reinforcement mesh for AAC applications. The M-System AAC is operated in 2 to 3 shifts per day and achieves an output of approx. 4,000 meshes per day.

The M-System AAC high-performance cage welding plant

Two fully automated Twin-MSR straighteners and cutters produce the line and cross wires for the mesh in the required lengths, quantities and diameters. The wires are then automatically transferred to the welding gantry. The resistance spot welding gantry is equipped with multiple welding heads whose computer control system allows the programming of welding parameters according to different wire diameters. While one pair or single meshes are being welded with connector bars made by another JIT working Progress machine, the stork takes the next meshes and places them in a similar line adjacent to the first one in order to keep to the high-speed volumes required. During the various handling processes the welding gantry welds already the next meshes. The integrated Progress control system facilitates CAD-CAM input from a master computer and enables system monitoring and error diagnosis.

The company’s focus on quality, safety and innovation – together with the quality and performance of the AAC applications being manufactured at the plant – has seen CSR Hebel become a preferential contractor for builders, developers, resellers and installers, and a formidable supplier in the construction industry of Australia and New Zealand.

CONTACT

Progress Maschinen & Automation AG

Julius-Durst-Strasse 100

39042 Brixen/Italy

+39 0472 979-100

CSR Hebel

Triniti 3, 39 Delhi Road

North Ryde NSW 2113/Australia

+61 2 9235 8000