Hollow-core to support Convention Center in Nigeria

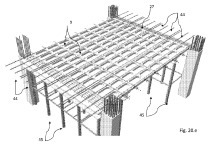

Following the announcement of the agreement between Spiroll and CCL, the first major project between the two companies was the setup of a new hollow-core factory in Abuja, Nigeria. The company in question, I.T.B. Nigeria Limited, is producing 200,000 m2 of Spiroll slabs to supply the construction of a new International Convention Center.

I.T.B., an African-based company with its headquarters in Lagos, is focusing its commercial energies on providing high-quality civil engineering and construction. Their clients are some of the most prestigious in the world, including government agencies and multi-national corporations.

Working together, Spiroll and CCL supplied the machinery, services and project management that has ensured a smooth delivery on the contract. The Abuja factory is now producing over 500 m2 of high quality hollow-core slabs per day on four casting beds 120 m long, in five different depths from 150 mm to 360 mm.

Production has hit the ground running with the Universal Extruder, alongside a complete range of ancillary Spiroll precast concrete machinery, allowing the staff in the factory to quickly maximize production efficiency.

Minimum of 10 MPa

difference in early strength

A multi-angle saw provides fast and accurate cuts at any angle in the hollow-core slabs, and is very easy to use. The bed cleaner allows the production staff to clean and prepare the beds in less than 15 minutes, requiring only one man to operate. This saves considerable time on what is normally a labor-intensive process.

A comprehensive maturity curing system with a boiler and under-bed heating is giving a minimum of 10 MPa difference in early strength, allowing the production operative to cut and lift the hollow-core slabs less than 13 hours after casting.

ITB Factory Manager Alex Abdelahad said: “The importance of Spiroll machines is that they are easy to operate and maintain, with minimum manpower. The extruder provides a high quality hollow-core slab with the absence of cracks or weak spots on it.”

The factory and the Convention Center itself will stand as testament to the continued success of the partnership between Spiroll and CCL.