Hybrid concrete tanks for future-proof energy storage

Energy storage systems are becoming increasingly important in the course of expanding generation from wind power and photovoltaics in order to resolve the residual load issue in electricity grids. Electricity storage can be complemented by heat storage systems to relieve grids of some of their burden by converting excess electricity from distribution grids to heat and to subsequently use it for heating purposes (power-to-heat), rather than disconnecting wind turbines from the grid. In the event of supply gaps, future plans provide for an increasing share of combined heat and power systems to be used to generate electricity that cannot be supplied through the grid highly efficiently in a distributed arrangement. The thermal energy thus produced needs to be stored efficiently in order to effectively utilize the heat generated in either of these scenarios. This concept makes it possible to efficiently stabilize electricity supply whilst adding flexibility to the system [1].

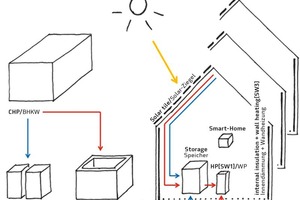

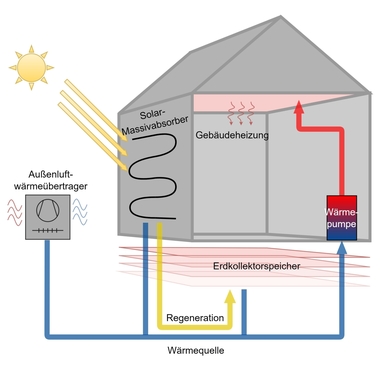

Nowadays, hot-water storage tanks are primarily used for thermal energy storage. In contrast to this approach, the authors of this paper are currently conducting research to identify storage concepts suitable for creating high energy densities at low to medium storage temperature levels. For example, concrete storage tanks should be developed that are particularly well-suited to ensuring low-loss heat storage as part of future-proof energy concepts for buildings and urban neighborhoods. More specifically, storage systems suitable for underground installation in front of buildings are being considered that can also be interlinked across the neighborhood to convert locally generated electricity (PV), generated heat (by solar-thermal and geothermal systems with a heat pump), and excess electricity no longer absorbable by the distribution grid on days with high PV and wind power yields to heat and to store this heat for subsequent indoor heating [2, 3] (Fig. 1).

Proposed solution and project objectives

Hot-water storage tanks are sensitive heat storage systems. Heat absorption or release requires a tangible change in temperature because the storage medium is either heated or cooled. The amount of heat that can be stored results from the product of temperature difference, mass of the storage medium, and specific thermal capacity. In addition to sensitive heat, latent heat storage systems store the energy needed for a phase change (change from the solid to the liquid or from the liquid to the gaseous state). In practice, the transition from the solid to the liquid phase is used. Latent storage is associated with benefits compared to sensitive storage because it provides the capacity to store large amounts of thermal energy already at small temperature differences. Furthermore, the temperature level remains constant for a long period during absorption and release. This is why latent heat storage systems are particularly attractive when it comes to utilizing heat in buildings [2].

However, the cost of latent heat storage is significantly higher than that of sensitive storage systems. This is due to the fact that the former includes phase-change materials (PCMs). Currently, organic PCMs (paraffins) are primarily used whose price usually exceeds €10 per kilogram. They provide the advantage that paraffins with a wide range of phase-change temperatures are commercially available and that these PCMs are chemically inert and non-toxic. On the other hand, they are combustible, and their energy density is relatively low. For instance, the melting enthalpy of paraffins amounts to about 240 kJ/kg, which means that their latent heat storage potential equals approximately 190 kJ/liter at a density between 0.7 and 0.9 kg/liter.

Alternatively, inorganic PCMs can be used, such as eutectic water-salt solutions and salt hydrates. Compared to paraffins, these materials incur lower costs and are traded at prices between €0.30 per kilogram and €2.00 per kilogram depending on the type and amount of material. Even though salt hydrates exhibit a melting enthalpy similar to that of paraffins, their significantly greater densities (1.4 to 1.6 kg/l) result in a volume-related energy density between 250 and 400 kJ/liter (see Table 1). Salt hydrates provide the benefit of being non-combustible, which is a characteristic of particular interest to the construction industry, but they are also associated with some disadvantages. For instance, they are susceptible to subcooling and vitrification, and they have a low vapor pressure and high viscosity. Depending on the type of salt, they may also exhibit high acidity and reactivity of anions. However, the tendency of salt hydrate melts to crystallize only after excessive subcooling, or not at all, poses a particular challenge that makes it much more difficult to use these materials in technical applications. Consequently, salt-hydrate-specific crystallization initiators are sought that would enable crystallization at a significantly lower level of subcooling [4].

Building-related and neighborhood-integrated energy storage

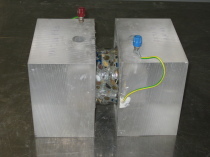

The authors aim to develop PCM-based thermal energy storage systems to market maturity and to optimize their absorption and release behavior to enable utilization of the energy locally generated by PV or combined heat and power systems in the building or in the neighborhood even if there is no demand in the specific building or in the smart grid of buildings that extends across the neighborhood. Depending on the salt hydrates selected, a wide range of concrete technology requirements arise for the production of concrete tanks that are sufficiently resistant and thus suitable for energy storage using salt hydrates. For complex PCMs, an innovative, hybrid, double-shell concrete tank is thus used that was developed jointly by the IWB and Mall GmbH as an acid-resistant storage vessel in a ZIM research project [5]. Such tanks can also be used for PCMs based on salt hydrates because of the optimized high-performance concrete mix used for the inner liner exposed to high chemical, physical and mechanical loads. Concrete tanks can be precast in sizes from 1 to 22 m3 and installed underground (Figs. 2 and 3). These tanks come at a relatively low cost and can be cascaded to any size to implement integrated storage concepts for entire urban neighborhoods [6].