In transition: The new generation of the precast concrete industry

In 2019, entrepreneur Jens Niendieck acquired what is now BWN GmbH – Betonwerk Niendieck based in Bad Laer in the German State of Lower Saxony, followed by consistent modernization and remarkable growth. This was achieved by expanding the company’s product portfolio, continuously improving existing products, increasing the number of employees from three to 28, and an excellently filled order book. BFT International editor Karla Knitter visited Jens Niendieck in Bad Laer and gained valuable insights into a precast plant in transition.

Why sell/buy a precast plant?

More often than not, corporate succession planning is not an easy task. In the case of BWN, the previous owner of the business founded in 1911 lacked a suitable successor, which is why an external buyer had to be found for the company. Niendieck, who had worked as a sales manager for large precast operations before becoming self-employed, was looking for such a challenge at the time. “I wanted to be my own boss. I immediately saw the great potential of this precast plant,” Niendieck reports.

At that time, only truck scale decks were produced in Bad Laer by the then three employees – for a single customer. This changed dramatically after Niendieck, as the new owner and managing director, embarked on extensive modernization and restructuring from 1 January 2020. Today, 28 people work at the Bad Laer plant. The prevailing shortage of skilled workers affects BWN only to a limited extent. Some of the 19- to 65-year-old employees are completing further training in parallel to their jobs. In the long term, Niendieck also intends to train people directly at the premises. “The wide variety of activities makes working with us quite demanding, but it brings a lot of motivation and fun at the same time,” Niendieck tells us.

Enjoying a very high order intake overall, the business rests on different main pillars today: The product range includes truck scale decks, track and vehicle pits, cable ducts and shafts, equipment foundations for transformer stations, light pole bases, special slabs for structures and traffic areas, BWN blocks, and custom-manufactured items.. Currently, its premises extend over 3 hectares, but Niendieck has already paved the way to further growth by purchasing neighboring plots of land.

Challenges and modernization activities

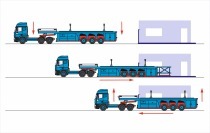

Jens Niendieck faced a challenge that should not be underestimated: the small, very convoluted factory buildings operated by the business, which provide little or no space for using cranes. Niendieck currently solves this problem with intelligent, custom formwork systems. The plant uses hydraulic forms that can also be transported without a cargo crane. In the long term, however, the construction of additional buildings is planned. “We always put everything to the test..”

In areas where a crane can operate, a state-of-the-art mobile gantry crane from Combilift Ireland (built in April 2022) does so. This piece of equipment was tailored to the specific BWN requirements. All features of the crane can be remote-controlled. The mobile gantry crane has a maximum lifting capacity of 40 tons and a maximum lifting height of 6.27 m. It is also suitable for being driven on gravel surfaces, having the capability of coping with gradients of up to 5%. Yet this crane is but one example of the cutting-edge equipment installed in an old precast plant.

The concept of combining old and new also works for the company’s mixing plant – the Eirich system currently in use dates back to 1987. This relatively old but very robust unit was upgraded in 2020 by adding a new digital control system. Its installation enabled the mixing plant to meet the current requirements of the company’s various mainstays. “Continuous modernization of equipment and thus ongoing investment is imperative,” says Niendieck.

The Elba gravel scraper was also rebuilt and automated in 2022. In addition, new compressed-air cement dust extraction systems from Kurz Silosysteme were installed this year.

Custom manufacture

The company’s mainstay, custom manufacture, is Niendieck’s response to an increasingly demanding market. “Timing on the construction site in particular is becoming increasingly important,” he says. To ensure that schedules are met, BWN supplies contractors with targeted prefabricated solutions for in-situ concrete projects. The company responds to customers’ requirements with maximum flexibility. Manhole covers or embankment slabs, for example, are supplied as needed – in any quantity. This approach is also applied to specific, order-related requirements. The close interaction during projects results in long-lasting customer relationships.

Production of truck scale decks

Truck scale deck production was the precast plant’s only line of business before it was taken over, and it continues to play an important role. Production has undergone major changes in recent years, and the components have become leaner and more efficient, which is extremely beneficial in terms of shipping. Truck scale decks are shipped to customers from across Germany and neighboring countries, and Betonwerk Niendieck has become one of the leading suppliers in Europe.

Cable ducts & Co.

The portfolio offered by the Niendieck plant also includes the serial production of cable ducts and conduits for transformer stations. “With these products, we are contributing to the energy transition,” says Niendieck.

A special project: Light pole bases for Wilhelmshaven

A recent order placed with the precast plant includes the production of 32 light pole bases for the quay extension of the Wilhelmshaven Naval Base Command. The items measure 1.5 × 1.5 × 1.75 m and weigh approximately 10 tons each. The head portion has a special design characterized by an inclined section with a truncated pyramid shape. Production of the light pole bases includes curing in custom forms in an upside-down position. The quality and the recipe of the concrete is also of paramount importance since it must meet the added challenge of being resistant to seawater. This requirement is met by a specially adjusted concrete recipe.

Industry association work and vision for the future

Jens Niendieck is eager to share his experience with other young businesspeople and will therefore be involved in the future as a speaker for the Osnabrück Economic Development Corporation (WIGOS), which is a key partner for businesses in Osnabrück and supports them in everything from assisting with major capex projects to promoting innovation and providing advice on subsidies. “I myself benefited from friends at construction contractor businesses who acted as mentors when I took the plunge into self-employment. Now I am able to share my knowledge.” For the entrepreneur, the 180-degree turnaround of the company through consistent modernization is not an isolated case. “Our industry is undergoing a major transformation,” he says. He intends to grow the business further through acquiring additional production sites and is interested in a thorough exchange with industry colleagues.

CONTACT

BWN GmbH Betonwerk Niendieck

Bielefelder Str. 60

49196 Bad Laer/Germany

+49 5424 9205