Innovation: Chekker

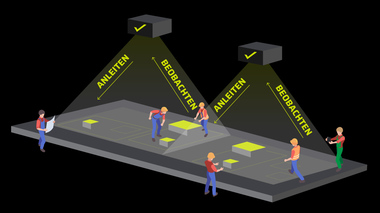

The precast production is confronted with two main challenges: There is, on the one hand, an increase in the complexity of the needed precast concrete products. On the other hand, however, there is a decrease in employees’ qualification. The combination of these factors leads to more opportunities for error and slows the workflow at the expense of profitability and quality. Chekker offers a solution for those problems, according to the manufacturer. In scale 1:1 and with its integrated and automated quality testing as well as time data recording, a detailed instruction is projected on the working surface. Therefore, no paper-based plans are needed, which saves resources without the loss of quality or efficiency.

Error avoidance due to 3D-Augmented-Reality

The software, that has been invented specifically for Chekker, in interaction with the hardware, offers an instrument for precise projected images and measurements. All relevant information is displayed in 2D and correct in height. An optional 3D-augmented-reality-visualization on a tablet, smartphone or through HoloLens enables a practical application of the digital design. With its integrated and automated quality testing, Chekker detects whether built-in components and reinforcements are being selected and installed in accordance with provisions. Any deviations are reported and shown immediately. It reacts to changes in the positioning of flat or inclined pallets and automatically adjusts the calibration for accuracy. Time data recording autonomously measures the duration of the individual work steps, which allows an immediate analysis and recalculation for the precast production. The result is a digital twin that offers a BIM as-built-model of the precast concrete.

CONTACT

Schöck Bauteile GmbH

Vimbucher Str. 2

76543 Baden-Baden/Germany

+49 7223 967-0