Concrete Rudolph opts for Chekker technology platform

Since the beginning of the year, the Concrete Rudolph precast producer, which is part of the Rohrdorfer group of companies, has been using the Chekker technology platform of the Austrian Beamionic GmbH. Chekker is an innovative combination of hardware and software, supporting the manual manufacturing workplace in a digital way. Paper plans are replaced by the full-scale (1:1) projection of CAD construction drawings onto the production surface. Thanks to augmented reality, the production of complicated thermal walls is much easier for the workers now while the sequence quality control ensures results of consistently high quality.

Perfect complement of manual processes

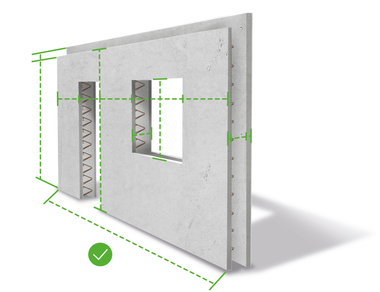

In case of structural components with finished surfaces often several material layers are overlapping. An interlocking of several elements when being assembled at the construction site requires a high fitting accuracy. Despite 2D production plans created up to the very detail and much knowledge and experience of all those involved, there are time and again uncertainties and discrepancies as far as the production of multi-layer, nested precast wall and solid elements is concerned. Therefore, potential improvements are constantly searched for in order to ensure a consistently high product quality. Using Chekker, Concrete Rudolph opts for a digital solution, complementing the manual process perfectly, with likewise optimizing the production process and product quality.

Optimization and documentation of working steps

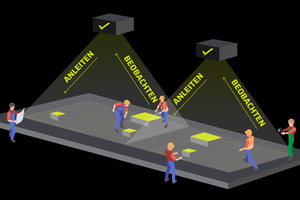

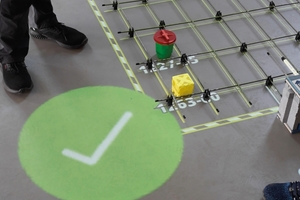

The solution is a combination of software and hardware. The specifically developed software in interaction with the hardware, consisting of industrial cameras and PCs as well as a high-lumen projector, is a precision and measuring device. The production workers get a step-by-step instruction projected on the working surface in a 1:1 scale, that can be understood and implemented intuitively. A sequence quality control takes place additionally. Not until a working step has been finished completely and properly, for example, all mounting parts have been incorporated correctly, the next working step is released. The multi-colored, animated 3D hologram of the workpiece using augmented reality allows the worker to inspect the building component from any angle and perspective in actual size on the working surface and thus understanding the same. As-built BIM data, a protocol of the quality control and an associated photo documentation are created simultaneously.

„Chekker convinces not only by a considerable simplification of our work processes and the documentation of our work. Our workers simply have even fun working with the technology,“ states Manfred Platzer, head of the precast division at Rohrdorfer.

CONTACT

Rohrdorfer Baustoffe Austria GmbH

Lagerstraße 1-5

2103 Langenzersdorf/Austria

+43 50543 1100

kommunikation@rohrdorfer.at

www.rohrdorfer.at