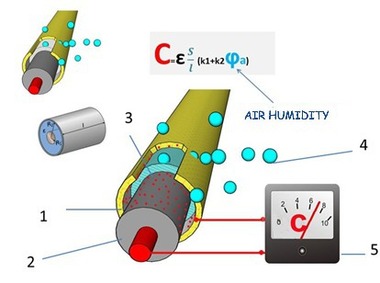

Innovation: IoT 4.0 real-time

measurement within precast elements

Monitoring curing times is a particularly complex and expensive step in the process of manufacturing concrete products. Failure to establish the strength development of precast concrete elements may lead to damage or production faults. The manufacturer may also have to schedule long buffer periods.

Maturix is a ground-breaking tool that uses wireless sensors to measure the curing time and strength development within the concrete product. Measured values are directly transmitted into the cloud, and results are directly available to the user. Maturix is easy to use and can be implemented completely within only a few hours. This flexible solution is suitable for use both at the precast plant and on the construction site. The integrated 4.0 sensors feature a replaceable external cable that is embedded in the wet concrete of the element and subsequently used for a complete measuring cycle. However, real-time monitoring costs remain low because the sensor can be reused many times.

1 million measurements per day

A Danish precast producer has been using Maturix since the beginning of 2017 for its manufacture of prestressed precast floor slabs, prestressed girders, and sandwich wall panels. The 4.0 sensors are mounted in all production areas; results are displayed on large 50’’ monitors located in each production department.

After six weeks, production waste was reduced by 35% whilst output grew by 15%. The time required for producing prestressed elements was shortened from ten to eight hours without compromising the prestressing effect or causing other damage. Furthermore, the exact determination of curing times enables quicker and safer demolding of precast elements.

Sensohive Technologies, the Danish provider of the Maturix solution, has been on the market since 2015. Its customer base currently encompasses 22 countries, and the company won the Nordic Start-up Award in the “Best IoT Startup” category.

According to the company, Sensohive sensors perform over 1 million measurements and collect more than 200,000 customer data items per day.

Going forward, the company intends to further expand its business within Scandinavia, to Germany, Austria and Switzerland, the Middle East, and the Americas. Also, Sensohive will soon be launching an automated heating control solution.