Molding and heat curing of UHPC

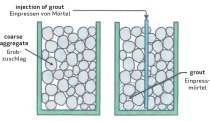

Various molding processes can be used for producing UHPC components, such as grouting, casting or extrusion. Casting is most commonly used. UHPC with good rheological characteristics is suitable for manufacturing precast elements in complex shapes. Fig. 1 shows the “kicker” (soccer table) that was produced from UHPC at the cbm (Centrum Baustoffe und Materialprüfung; Center for Building Materials and Materials Testing at Munich University of Technology).

Rheological properties such as viscosity, yield limit and thixotropic behavior are key to ensuring an impeccable molding process. These characteristics can be achieved by optimizing the mix design, selecting a suitable type and amount of plasticizer or applying an appropriate mixing process. For instance, additives such as silica dust, fly ash, limestone dust or blast-furnace slag have a significant influence on the amount of plasticizer required and thus on concrete workability. The use of limestone dust or silica dust with a lower specific surface considerably improved the workability...