Innovation: Via Domo Smart Wetcast – reinforced polyurethane molds

Since the introduction of the REACH regulation (European Chemicals Regulation), an increasing number of chemicals that formerly contributed to the dimensional stability of polyurethane molds are now forbidden for use. Finding substitutes for such chemicals, especially mercury, has proven only partially successful until now among the manufacturers of polyurethane products.

The reinforced molds, for which the company BCR Building Components Rimmele has applied for a patent, ensures, according to the manufacturer, optimal stability of form and dimensions. The molds are still sufficiently flexible, also for manual demolding. In addition, the design prevents dimensional changes and collapse of the side walls. There are two basic types of these molds:

Via Domo Smart Wetcast mold type S

The side walls of Wetcast mold type S are now for the first time reinforced with special, high-quality ledges (18-24 mm in width). These molds are self-supporting, and no cost-intensive production frames or production boxes are required. Both stand-alone molds and multi-compartment molds are possible, depending on the size of the production boards.

With this mold, a glass fiber mesh at the bottom of the mold is fixed circumferentially onto the integrated ledges. This prevents subsequent shrinkage or size increase of the polyurethane at the mold bottom. The low weight and the production frames or boxes that are no longer required greatly facilitate handling in production. In this way, these molds can be simply fixed to the production boards.

Via Domo Smart Wetcast mold type L

The side walls of the Via Domo Smart Wetcast mold type L, according to the manufacturer, are reinforced for the first time, as a worldwide innovation, with special 5-mm thick ledges integrated in the wall. This mold type is used with production frames or boxes.

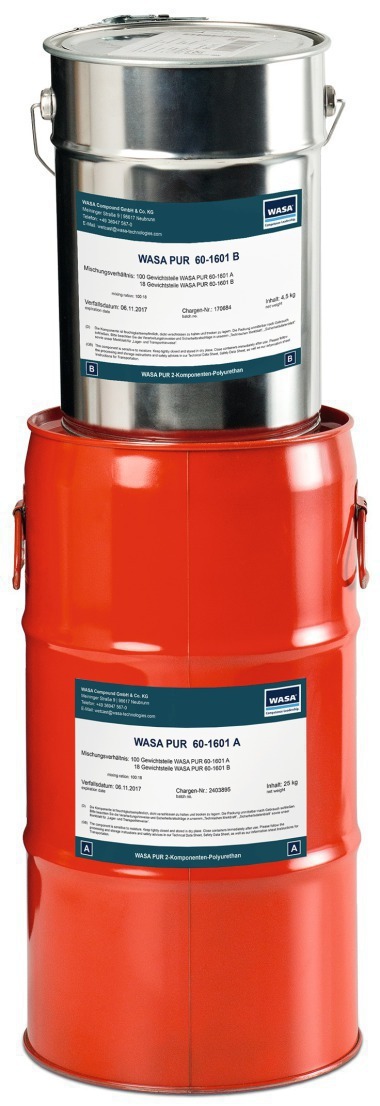

Undercutting is possible in the same manner as for conventional molds. The elasticity is retained to its usual extent. These molds, made of quality-tested high-quality polyurethane (Shore 60 A), ensure form stability and exact conformity to detail specifications for years. Aging is strictly limited to the effects of release agents, admixtures for concrete, and the demolding process.