Innovation prize for textile-reinforced concrete sandwich wall

The 2018 Innovation Prize of the Supplier Industry for Structural Concrete Products was awarded at the opening of the 62nd BetonTage convention on February 20, 2018 in Neu-Ulm. The first prize went to Solidian GmbH, Albstadt. The company was given the award for the development of a sandwich façade wall produced from textile-reinforced concrete. The second prize was awarded to CPC AG based in Andelfingen for their carbon-prestressed concrete slab (see page 24).

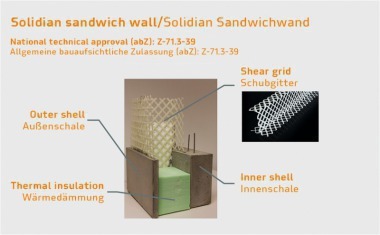

Sandwich structures with reinforced-concrete covers have proven their worth in Germany for many decades as a composite structure for the building envelope. Facing shells with a minimum thickness of 8 to 10 cm are required to protect the reinforcing steel from corrosion. Using the innovative textile-reinforced facing shells and glass-fiber shear grids manufactured by Solidian GmbH, on the other hand, enables the standard concrete cover to be reduced to 10 to 15 mm. The thinner design allows architectural-concrete elements to achieve material savings of up to 70% compared to a conventional reinforced-concrete element.

This reduces material costs and creates more space; it allows for additional space to be created inside the structure especially when building close to surrounding properties. Transport and assembly are additionally simplified significantly due to the considerable reduction in weight. An extended useful life is also guaranteed, since textile-reinforced concrete is not prone to corrosion. Solidian was granted the first national technical approval for this type of construction in 2017.

First entirely textile-reinforced sandwich façade

Solidian GmbH is a manufacturer of non-metal reinforcements and produces, among other things, the AR glass-fiber reinforcements (brand name: Solidian Grid) for the centrally reinforced, 30-mm thin facing shell, as well as connecting grids for the precast industry. The connecting grid (Fig. 2) transfers loads between the facing shell and supporting shell, thus significantly reducing thermal bridges; in this way, the innovative connecting grid contributes to optimizing the energy efficiency of buildings.

The “Eastsite VIII” building in Mannheim is the first building in the world featuring a façade realized entirely as a textile-reinforced concrete sandwich (Fig. 3). The anthracite-colored, acidified concrete surface contrasts with the golden-colored, anodized sheet metal surfaces of the window jambs. The advantages offered by textile-reinforced concrete sandwich façade elements convinced and prompted the client to realize two additional office buildings comprising up to five stories using this construction method. The project was realized by Solidian in collaboration with the client B.A.U. GmbH & Co. KG, the architectural office Fischer Architekten, the precast concrete plant Dreßler Bau GmbH, the Institute of Concrete Structures at RWTH Aachen, and the Regional Council of Tübingen.

Innovative products, processes, services

The Innovation Prize of the Supplier Industry for Structural Concrete Products is offered annually by FBF Betondienst GmbH, host of the BetonTage convention, and BFT International, the trade journal for the industry.

The prize is awarded to exemplary innovative products, processes and services offered by the machine, software and supplier industry of the precast concrete sector. Important selection criteria for the award include the level of innovation and the originality of the proposal, its relevance for the precast concrete sector, its market and application potential, as well as the consideration of technological standards.