Innovative precast reinforced-concrete hollow-core slab system changes Central Asian cities

The innovative Motus building system allows for constructing not only solid and sandwich walls but also three-dimensional hollow-core slabs in many shapes and designs. EGI, an Uzbek construction contractor, relies on the industrial prefabrication of these elements based on automated processes and the expertise provided by Vollert, the German equipment manufacturer.

The innovative Motus building system comes with a number of advantages, including affordable housing, new architectural highlights and high earthquake resistance. Its range includes not only solid and sandwich walls but also three-dimensional hollow-core slabs in many shapes and designs. EGI, an Uzbek construction contractor, relies on automated manufacturing processes and the expertise provided by Vollert, the German equipment manufacturer, for the industrial prefabrication of this building system.

Nowadays, urban architecture has to meet a large number of different needs, such as applying sustainable and resource-efficient construction methods while ensuring the quick completion of low-cost, affordable housing projects for the growing number of people living in mega-cities. Other important factors include quality of life, living comfort and attractive architectural features, as well as an effective response to the increasingly severe climate- and weather-induced changes and geophysical natural disasters. Currently, 1,300 earthquakes of magnitude 5 to 6 occur each year, causing severe damage and a death toll of 50,000 worldwide.

This is where innovative building systems come into play. Since the 1980s, there has been a growing demand for industrially prefabricated concrete elements, which has become the leading construction method particularly in Europe. Yet building systems are also increasingly being used in Russia and the CIS countries. Particularly during the last decade, construction technology has evolved significantly, including enhanced materials and improved production processes. “However, up to now, it has been virtually impossible to construct high-rise residential buildings in seismically active regions while increasing the load-bearing capacity of walls and floors and combining these structural features with attractive architectural highlights such as intricate designs and color schemes,” explains construction engineer and building designer, Roman Kusmichev.

Motus building system provides earthquake resistance and many other benefits

Kusmichev has been one of the driving forces behind preparing initial drawings and architectural designs in order to implement the new building system developed by the construction engineering team at Vollert, the German equipment manufacturer. He contributed his comprehensive hands-on expertise as well as a huge amount of data and statistics stemming from his previous career in the former USSR.

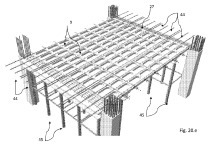

Back in 2015, Vollert had already developed a building system tailored to the needs of Chile, an earthquake-prone country, jointly with the construction contractor BauMax and the earthquake specialists at Sirve SA. Vollert transferred this expertise to the specific seismic conditions in Uzbekistan. For this purpose, the German supplier developed a new structural building system for residential buildings for the Uzbek developer Orient Group in 2017. Since the 1990s, the city of Tashkent, with over 2 million inhabitants, has been the political, cultural and economic hub of Uzbekistan. New residential buildings are constructed just as quickly as cutting-edge shopping malls and community projects. Nowadays, projects can be completed within much shorter periods thanks to modern architectural options combined with industrial prefabrication. In this context, earthquake resistance is of paramount importance because Uzbekistan is located in a high-risk seismic zone. To ensure its structural resistance even in the event of a major earthquake, the new building system includes specific design features and combines prestressed hollow-core slabs with insulated sandwich walls. The latter are equipped with additional connecting reinforcement and caissons to absorb seismic actions. In October 2018, the earthquake resistance of the building system was verified. For this purpose, the shell of a nine-story residential building was subjected to a simulated earthquake of magnitude 9 – the KazNIISSA Institute for Seismology used custom-designed eccentric vibrators to generate a strong vibrational pattern that largely replicated a real earthquake.

“It is predominantly floors, the floor structure and a precise, stable floor-wall connection that ensure the structural stability of the system in the event of major impacts such as an earthquake or an explosion caused by a gas leak,” adds Igor Chukov, Executive Sales Director CIS/Russia at Vollert. “With the Motus building system, we have contributed our expertise from previous successful projects in Chile and Uzbekistan while still improving the system, which is based on the custom-designed, truly innovative Motus reinforced-concrete hollow-core floor slabs. Combining this new floor design with solid precast elements for internal walls and insulated sandwich walls ensures the high seismic resistance of the system.” Yet earthquake resistance is just one of the many benefits of the new system. “Previously, prefabricated building systems had seriously limited the range of architectural options and creative freedom,” Kuzmichev explains. “What has really counted up to now was the low-cost, industrial prefabrication of walls and floors. The associated high degree of standardization restricted to only a few precast element designs imposed limitations in terms of designing attractive façades or bay windows as well as the basic layout of apartments.” The Motus building system has evidently changed this situation. Even the very first drawings strongly fascinated developers and construction contractors. “Simple building systems using only square or rectangular shapes have become a thing of the past. In contrast, the new building system enables us to construct, for instance, intriguing 3D façades with projecting balconies and bays.” This design freedom is made possible by new options for connecting walls with floors as well as structural components such as staircases.

Novel prefabrication method for reinforced-concrete hollow-core slabs

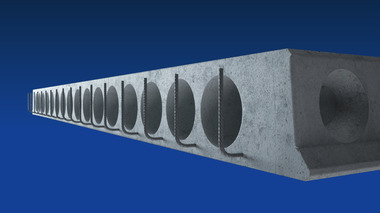

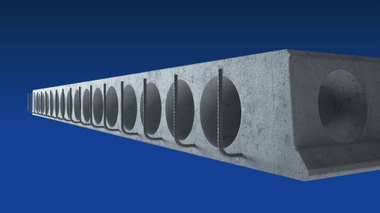

The Motus building system was first showcased at the 2019 bauma in Munich. Its key novelty are the integrated prestressed reinforced-concrete hollow-core floor slabs. Conventionally prestressed hollow-core slabs exhibit a superior performance and save significant costs and time compared to solid concrete floors, but they are often missing truly earthquake-resistant characteristics and provide only limited options for inserting reinforcing mesh or additional connecting reinforcement. Despite initial solutions allowing for their use in seismically active regions, such elements often fail to perform in the event of an earthquake, with fatal consequences. Frequent modes of failure involve the interfacial area between the top of the floor slab and the concrete topping, fracture of the underside, or failure of the load-bearing I profile webs under severe impact. Improving this situation was thus guided by a single overarching objective: saving lives. “The typical failure pattern can be overcome by including an additional, projecting reinforcement directly embedded in the hollow-core slab, a fixed, direct connection of the reinforcement between the individual elements, and a flexible hollow core geometry ensuring sufficient shear resistance,” explains Andreas Titze, concrete technology specialist at Vollert. Another drawback was the previously applied extrusion process seriously limiting the range of available floor slab widths, thus making it impossible to integrate utility ducts, blockouts or lifting anchors.

Motus hollow-core slabs meet a number of these earthquake-relevant requirements. The integrated reinforcing mesh and connecting reinforcement allow for a firm-fit, earthquake-resistant on-site erection and assembly of the floor slabs. Their load-bearing capacity increases significantly because tensile forces can be absorbed on all sides. In the longitudinal direction, it is very easy to accommodate a prestressing wire overhang while, laterally, additional reinforcement can be integrated to firmly connect the individual slabs to each other. The flexible void geometry and structure ensures a shear resistance level according to the specific project requirements. “At the same time, we wanted to produce much wider slabs of up to 3 m with thicknesses ranging from 12 to about 26.5 cm, which would reduce the number of required on-site crane lifts and the time needed for their installation considerably compared to extruded hollow-core slabs. We also aimed to produce, for the first time, earthquake-proof hollow-core slabs in a variety of shapes and dimensions, which opens up entirely new architectural design options,” Kusmichev explains.

Vollert developed an innovative production process in order to respond to all these practical needs. Instead of employing an extrusion or slipforming method, the new hollow-core slabs are produced on a pallet circulation system. Each prestressed concrete hollow-core slab is manufactured exactly to the specified shape and dimensions in a waste-free process, rather than cutting the continuous floor slab to the required size after concrete pouring. The production line includes a newly designed machine with cylinders to create the hollow cores. These cylinders are inserted into the slab form only temporarily during concrete pouring. The number and shape of the voids can be varied very flexibly, which would not be possible in an extrusion process on long casting beds. In addition, the new process makes it possible to insert cable conduits, utility ducts for water supply and ventilation, and custom embedded parts, thus opening up completely new options for structural or technical designers. A single-strand prestressing unit ensures the application of the specified tensioning forces. For this purpose, the production pallets were designed such that the maximum possible prestressing forces can be transferred to the precast element.

A complete system for landmark construction projects in Uzbekistan

Orient Group had previously used the Vollert equipment technology to successfully complete construction projects in Uzbekistan. In 2017, the company engaged in initial talks with Euro Global Invest (EGI), which has been doing business in the construction sector since 2016. This Uzbek construction material supplier produces materials for the city of Tashkent and the neighboring regions, including granite chippings and sand but also ready-mixed concrete for large-scale construction projects within the city limits, such as the rapidly growing Tashkent City mega-project. Together with Ipoteka Bank, the company decided to strategically expand its construction portfolio. “Already in the initial discussions, we got convinced of Igor Chukov, the entire Vollert project team and the Motus building system,” explains the CEO of Euro Global Invest, Djamchid Inagamov. “Right from the start, our aim was to manufacture the complete building system on a single, consistently designed production line.”

The ground-breaking ceremony for the precast plant in a Tashkent suburb followed almost six months after the final contractual negotiations. “The Motus prestressed concrete hollow-core slabs and the solid and sandwich walls required for completing the building system are manufactured simultaneously, plus a number of other structural precast elements including columns, beams and stairs, as well as conventional, slipformed hollow-core slabs for industrial construction,” says Inagamov. “This output is equivalent to an annual formwork area of just under 700,000 m².” Vollert, the equipment specialist, took care of the complete transfer of knowledge and expertise, particularly in relation to the Motus building system, and assumed a general contractor role for the complete production equipment and machinery as well as automation, software design and implementation.

“In this process, we cooperated very closely with our trusted system suppliers Liebherr, Elticon, EVG, and Nordimpianti. We thoroughly discussed many options, always with a view to the requirements imposed by the Motus building system. The Vollert construction engineers and project managers coordinated all related processes and work steps,” describes Roman Burau, head project manager at Vollert. The plant design excels with its high degree of automation, efficient production sequences and state-of-the-art equipment technology. “Just like in the automotive industry, we have implemented processes that are standardized to a great extent. Highly efficient robots and machines and the cycle-based manufacture of wall panels and floor slabs on a circulation system make it possible to achieve maximum productivity in the production process.” For instance, smart-cast automated concrete spreaders ensure optimal concrete cycle times as well as precise concrete batching in accordance with the zero-error strategy in the manufacture of both the Motus hollow-core slabs and the solid wall panels. A central Elticon bucket conveyor distribution line was installed for supplying concrete directly to pouring. The Vario Cure curing chambers, state-of-the-art storage and retrieval units and reliable transport and loading sequences all use cutting-edge technology. Electrically driven Vario Smooth troweling machines are used for surface finishing. “This is how we produce high-quality walls and floors that conform to architectural concrete standards,” explains the EGI CEO, Djamchid Inagamov. “We also installed a smart-set shuttering robot in the solid wall production line, a latest-generation multifunctional robot that combines innovative technology with high advance rates in terms of travel speed and acceleration. Depending on the type of wall or floor, a CAD/CAM system is used for positioning the stop-end formwork and plotting the contours of embedded parts and reinforcement components.”

The mesh welding unit and the lattice girder production line supplied by the Austrian manufacturer EVG are also fully automated. They utilize state-of-the-art robotics and are fully integrated into the control system.

Partnerships with EVG, Elticon, Nordimpianti and Liebherr

The reinforcement production line was installed centrally as the core piece between the hollow-core slab and solid wall production lines. A sophisticated Vario Safe safety concept ensures that hazards are kept to a minimum.

An EVO e120 extrusion unit supplied by Nordimpianti was installed for additionally producing standardized hollow-core slabs for industrial construction. This extruder is designed for the manufacture of up to 1.2 m wide and 22 cm thick floor slabs. Depending on the specific project and order, up to six voids can be produced using the existing form insert. In addition, volumetric and structural precast elements are produced on custom-designed stationary mold systems. For this purpose, several high-performance tilt tables for extensive custom elements, a hydraulic duplex column mold and a duplex beam mold were installed. The production line also includes a duplex Variostep stair mold from the Vollert custom mold range to allow for a particularly flexible design and the production of right and left-turn staircases with up to 20 steps in an upright position. A modular side wall allows for the production of 900 to 1,500 mm wide stairs with steps in a continuous range from 220 to 320 mm and a pitch between 150 and 200 mm. Stairs are produced on the framing side, which ensures architectural concrete quality on three sides. In addition, a landing platform can be easily installed at any step of the stair thanks to the rear steel panel that can be moved horizontally and adjusted in its height. Besides staircases, a custom block mold makes it possible to also produce ventilation shafts for the new construction projects.

A Liebherr concrete mixing unit was installed as the central source for supplying structural and ready-mixed concrete to all in-house concreting processes and external sites. The integrated ring-pan mixer allows for an output of 2.25 m³ of concrete per batch.

Vollert Control Center as the “brain” of precast element production

The automated production equipment used at EGI ensures a consistently high quality standard, but the implemented production control system is just as important for achieving maximum productivity. The Vollert Control Center (VCC) is the central interface for transferring the structural data taken from the architect’s designs to the ERP system and the production equipment. Cycle times and automated pallet allocation are optimized continuously while controlling all machines, automatically tracking and processing relevant data, managing retrieval sequences and curing times, and providing a large number of statistics. “This is why the VCC is often referred to as the brain of the modern precast plant,” adds Igor Chukov of Vollert. “At EGI, the challenge was to integrate the production equipment of all system partners into the control system. For us, both factors – the integrated production equipment and

the smart control system – provided the cornerstones for optimizing the precast element production launch at EGI.”

Successful project completion even in times of Covid-19

Since March 2020, the first residential buildings have been constructed in Tashkent on the basis of the designs submitted by the team of architects headed by chief designer Roman Kusmichev. In this process, the architectural models and ground plans were again modified to cater to the religious requirements in the region. The custom-designed, innovative architectural elements that make the shape and the design of the building unique are complemented by colored concrete, which requires a specific mix design. Concrete technology specialist Andreas Titze comments: “Blending the pigments with the concrete constituents creates a high-quality colored architectural concrete. We thus get fully and permanently colored precast elements that truly stand out in visual and architectural terms. In this process, we retain the outstanding characteristics of concrete as well as its durability, and the colored concrete even keeps its characteristic texture.” At the same time, varying shades and nuances lend a natural appeal to the surface. All the pigment layers adhere to the surface permanently and cannot be detached by wear or weather impact. The different shades remain invariably visible even in the event of minor damage to the surface.

“For us, the Motus building system is a sustainable, future-proof concept. It’s a true evolution. Despite the high degree of standardization, we combine significant architectural features with earthquake-proof construction for the first time in Uzbekistan,” says Djamchid Inagamov of EGI. “At the same time, we build in a resource-saving manner and create affordable housing within an exceedingly short period.” Despite the difficulties arising from the Covid-19 pandemic, deliveries to the first construction sites started right on time in summer 2020. “In this process, the comprehensive expertise that Vollert contributed to site management, quality standards and staff training was a true asset,” Inagamov adds.