Interdisciplinary collaboration of structural engineering, production engineering and engineering informatics

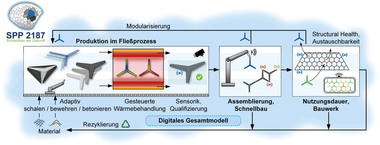

In January 2020, the Priority Program 2187, funded by the German Research Foundation (DFG), started. It brings together around 50 researchers from the fields of structural engineering, production engineering and engineering informatics. The objective of the research collaboration is to reduce construction times to a few days or weeks. Therefore, individual structural elements are divided into scalable modules. The modules are precast in stationary serial production, based on the flow production principle, and just assembled on site. Fabrication is derived from flow production concepts as known, for example, from the automotive industry. High-strength and ultra-high-strength concretes, high-strength steel and carbon are used. They all exhibit a high specific strength – i.e. a favorable ratio between strength and weight. The fabrication process is fully digitized in order to fulfill the required quality standards.

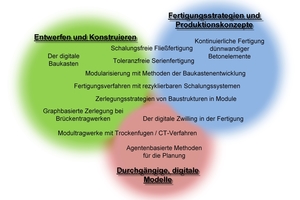

Design and detailing with respect to modularization

Production strategies and production concepts for scalable modules

Continuous, digital models for the processes of design, production and assembly

The program comprises 13 projects from 21 institutes and/or chairs. The figure shows the project topics and their allocation to the three research fields. Many projects cover two fields, often in collaboration between structural engineering and production engineering. First results are expected in 2021.