Building fast with serial-produced

construction elements – Priority Program 2187

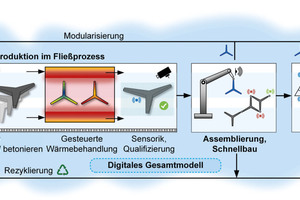

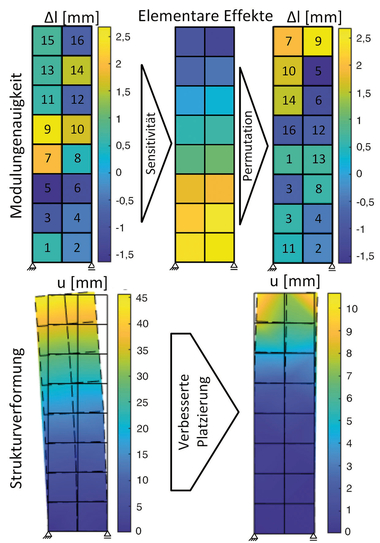

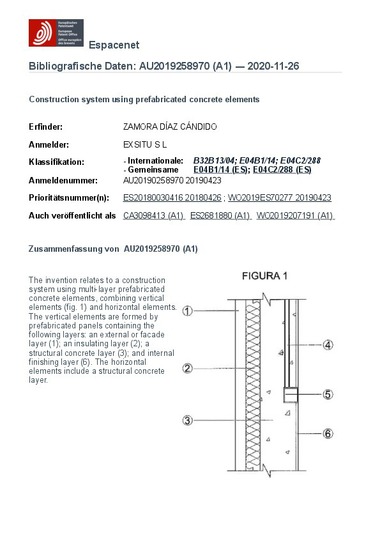

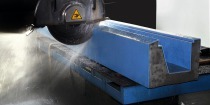

The future belongs to rapid construction. To enable this, structural construction elements must be entirely prefabricated. They must be light and their quality ensured. All that would need to take place at the construction site is assembly of the sensorially equipped individual elements (modules). The modules are monitored and controlled in production and installation and over their entire service life using adigital twin. In addition, they can be replaced.

The motivation for this is consistent avoidance of waste (lean management [1].) In concrete terms, material consumption will be drastically reduced. Savings of around 50 to 80 % are projected, compared to conventional in-situ construction methods [2]. Further, waiting times at the construction site caused by traffic jams, storage work or downtimes due to re-planning and errors will be minimized. The construction process will be consistently recorded to lean production.

In the Priority Program 2187, funded by the German Research Foundation (DFG), prefabrication of adaptive serial-produced construction elements made of high-performance materials [3] has been researched since the beginning of 2020. The work focuses on individualized production based on the flow principle. This is done by a group of 50 scientists from the fields of structural engineering, production engineering, building informatics, mathematics and control system. The contribution describes the state of developments and gives examples for new types of production based on the flow principle.

strategies in manufacturing systems. Procedia CIRP 29, 2015, pp. 86-91.

Bauinformatik - Präzisionsschnellbau der Zukunft. BFT International 86(2), 2020, S. 11.