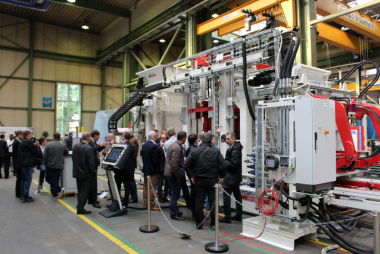

Large number of visitors in Burbach

Recently, the machine and equipment manufacturers Hess Group, SR-Schindler, Prinzing-Pfeiffer and Hess AAC Systems jointly presented themselves for the first time as Top-Werk to an interested trade audience on the occasion of the in-house exhibition held in Burbach.

Hess Group, domiciled in Burbach, has manufactured their thousandth machine in the meantime and even the first one has been finished with the new Top-Werk painting. Apart from the RH 1500-3 VA and RH 1500-3 MVA respectively, the smaller versions of the series, RH 600-2 VA and RH 500-3 VA, were shown too. Further highlights were the cubing system Servo-Pak 700, two mixing machines of the SM series as well as a finger car. Furthermore, they presented a new software, enabling the use of tablets and smart phones for uploading various static characteristics relating to the production of concrete blocks.

SR-Schindler, located in Regensburg, was the second company to present themselves with a complete treatment line and the corresponding sample blocks. Whether grinding, shot basting, coating, marbling, antiquing, curling or obtaining a wood look, the visitors found a wealth of treatment options. Apart from the “finishing touch”, SR-Schindler certainly offers appropriate machinery in order to begin with the production of the slabs and blocks to be treated at first.

Concrete milling machine and miniature model

Prinzing-Pfeiffer also aroused great interest presenting machines relating to concrete products for infrastructure such as pipes and manholes; this includes the concrete milling machine Primuss for milling outlets and channels with millimeter precision into the manhole base sections. In addition to that, the company presented molds for large size pipes, a pulley head as well as the new segment of cage welding machines.

Hess AAC Systems came up with a miniature model of a production plant for autoclaved aerated concrete that was accurate to the detail. In this way, every single process step of the production process could be shown step by step. The visitors could convince themselves of the advantages of this building material by the samples exhibited.

Company presented as a whole for the first time

At the end, Ralf Beier, CEO of the Top-Werk Group, drew a positive conclusion: “The in-house exhibition was and always is a good opportunity to present our company as a whole, while the production can run without interruption during the exhibition. Thus, not only our machines can be seen in operation, but also our well-organized and experienced team doing the daily work, which gives our customers an impression of the entire production process. Of course, new networks are built, experience is exchanged and negotiations are conducted too. However, we were as well aiming at a consistent presence of all our business units: We intended to present our new appearance and the expanded product portfolio, offering the customers a holistic solution from a single source.”