Logistics concept as safety measure

Time pressure in intra logistics is increasing more and more: Loading of trucks must take place in tightly defined time frames, safety and environmental standards must be met and customer requests taken into account. This requires fast response times as well as adapting to various needs. Transport of customized building components has to be safe, their storage should be space-saving, and their onward transport must be cost-effective and efficient.

30 years of experience in intra logistics

The innovative, family-owned company Trans Cargo Lifter e. K. has specialized in consulting service for internal transport solutions and special vehicle construction. This includes an optimum utilization of existing transport systems as well as a high level of service and flexibility. Integrated concepts are developed on the basis of 30 years of experience and the know-how of the cooperation partners Movella OY and Terberg Spezialfahrzeuge GmbH.

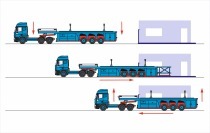

The Finnish company Movella OY was found in 2006 and has specialized in the development and manufacture of a wide variety of translifter systems. The principle of the translifters corresponds to a euro-pallet combined with a forklift truck. The translifter is positioned below the cassette, a strong transport platform for various payloads. The so-called cassette can be lifted and carried with the aid of the hydraulic lifting bogie of the translifter.

The Terberg Spezialfahrzeuge GmbH has gained many years of experience in the steel and precast concrete industries. The Hamburg headquarters is a subsidiary of the Dutch family-owned Royal Terberg Group. The company was founded in Benschop, NL, in 1869 and is still completely owned by the family. Today, the Royal Terberg Group comprises a number of operating companies serving various parts of the vehicle-related market (www.terbergspezialfahrzeuge.de).

„Keep it safe and simple“

The logistics model of Trans Cargo Lifter e. K. follows the K.I.S.S. philosophy: „Keep it safe and simple“, because safety on the factory premises depends on various factors. Rising hustle and bustle on the site leads to a reduced overview. Therefore, the trailers of Movella are equipped with lighting, warning signals and reversing cameras as standard. The fact that a signal color was chosen for the trailer systems also leads to better visibility on the factory premises. Brakes and load-dependent speed limits reduce the risk of accidents and damages to loads caused by time pressure.

A high noise level and unsecured walkways also increase the risk of accidents. The modern technology of the translifter systems reduces the noise emission in intra logistics. Swap bodies and containers do no longer scratch along the floor but due to the fact that the cassettes are accessible from below they can be removed almost silently.

The 180° swiveling seat of the Terberg tractor allows the driver always to sit in driving direction, thus providing him with an unrestricted vision. The translifter‘s steerable axles ensure precise and fast maneuvering. The gooseneck of the U-loader prevents tilting when picking up an inloader flat, with saving time and minimizing damages. The reversing cameras, in addition, provide for a proper collection of the loads. Due to the simplified way of loading goods, there is no need for the driver to leave the driver cabin, thus he is protected against the weather and saves even more time. In a specific example, the transportation of loads could be increased from 9 to 12 items per hour.