Modern and efficient formwork systems

For almost 50 years now, Weckenmann has been developing and manufacturing plants, machines and shuttering systems for products made of concrete. In the opinion of Benjamin Zeh, formwork expert at Weckenmann Anlagentechnik GmbH & Co. KG, the formwork system is the centerpiece of a modern production plant for precast concrete elements. The molds give the concrete its look and thus they are decisive for the good quality and high accuracy of the precast concrete element. „The requirements to concrete construction are permanently growing and are becoming more and more complex in terms of the quality and cost efficiency of the building structure. High quality and efficiency are more important than ever. This requires more consultation in the field of formwork systems but, at the same time, more flexibility in the products offered. Therefore, tailor-made solutions for the prefect precast concrete element are no longer indispensable,“ Zeh states. „The experience gained by Weckenmann over many years in development and production is evident in each formwork profile - from consulting to the design, manufacture and delivery to the customer, with the full-range of services provided by in-house specialists.“

Formwork system supplied to Russia

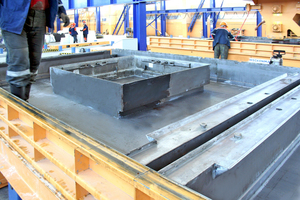

Recently, Weckenmann supplied several customers in Russia with completely new formwork systems together with a new circulation system for the production of floor slabs and wall elements. Those who are familiar with the Russian construction systems are aware of the challenges involved requiring special designs for the formwork systems used for the complex geometries of the precast concrete elements. The Russian construction system is very formwork intensive; and thus the challenge was to develop a flexible and clearly arranged formwork system that is eventually affordable.

The formwork experts and engineers of Weckenmann have analyzed every single concrete element in close cooperation with the customer. This precise analysis carried out in advance allowed them to develop a flexible formwork system for versatile use so that the number of formwork elements needed as well as the storage requirements could be reduced enormously. It is, for example, even possible to use the molds on both sides.

In addition to the standard, transverse and longitudinal formwork, the formwork systems developed for this purpose also include recess formers, for example, for windows and doors, which are necessary to shape the very complicated edges, rebar connectors and lifting anchors. This applies for both the production of solid wall and sandwich elements in various designs and geometries.

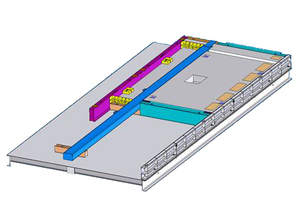

By using 3D animation, the customer gets an additional operating manual providing both management and factory workers with clearly structured and descriptive instructions to prepare the formwork for the panels in compliance with all quality requirements, within the shortest time possible. The engineering of the respective formwork systems represents the flexibility and decades of experience that Weckenmann brings to the table in this field.

Precast elements with a high degree of dimensional accuracy

The formwork and magnet systems are exclusively manufactured in the factory of Weckenmann to ensure that the customers will achieve proper edges and thus high qualities even in complex and profiled concrete elements owing to dimensionally accurate and stable molds. The precast concrete elements with a high degree of dimensional accuracy are achieved by means of a precise formwork system, and the tight tolerances in turn allow for short assembly times on the construction site later on.

Magnets are used for fastening the re-useable formwork profiles and recess formers. For this purpose, KS-coated magnetic strips are used - providing for a well-proven corrosion protection.

All components are perfectly matched since Weckenmann supplies both the formwork system and the complete machinery for the production of precast concrete elements. To understand the final product is an important fact in planning of an efficient production process. It is therefore cheaper to develop universal formwork systems for multiple products instead of different molds for each individual product. Consequently, the planned building components are analyzed in close coordination with the customer providing advisory support also concerning an optimization of the production process both for manual use and for robot technology application.

Six different formwork

profile series

For the different requirements in the precast concrete plant, We-ckenmann offers at present six different formwork profile series (see text box on page 18). The product portfolio is completed by accessories such as magnet boxes. These are used for fast and safe fastening of formwork profiles. A switchable magnet unit assists in an easy positioning on the pallet. The magnetic force is activated by pressing a switch button on the top. A new product in this field is the magnet box M2413. This magnet box in the same design as magnets M1811 and M2112, already included in the product portfolio, provides a holding force of 24,000 N. The formwork systems are used across the world on all continents combining know how „Made in Germany“ with the special requirements of the respective destination and customer.