„Modernization offensive“ at Oberndorfer

in Großwilfersdorf

Franz Oberndorfer GmbH & Co. KG headquartered in the Upper Austrian town of Gunskirchen is a market leader in Austria in the production of floor systems, wall systems and precast concrete elements. The group of companies, being managed in the fourth generation by Mag. Simone Oberndorfer since March 2020, has a workforce of approx. 1,000 people working in Austria and the neighboring location in Croatia as well as in the sales offices in Slovenia and Hungary. Apart from ultra-modern production plants, the company also offers comprehensive consultation and advice in respect of planning and possible applications of precast concrete products.

Project-specific framework conditions

At their Großwilfersdorf location, Oberndorfer is manufacturing precast floor slabs in addition to double wall elements; reinforcement had been installed there manually until today, which means costly in terms of labor and time. In the course of an evaluation of modernization options, it became apparent that the ambitious targets for an increase in productivity could only be attained with a fully automated welding line for reinforcement mesh integrated in the palette circulation system. The key requirement in this regard was a just-in-time production of flat mesh sheets, of bent up mesh sheets for precast floor slabs and of mesh sheets with block-outs as well as in various geometrical shapes. A particularly challenging aspect for providing the reinforcement were the tight tolerances of the overall dimensions along with the possible block-outs as well as the compliance with the precise position tolerance of the individual bars.

The equipment and machinery manufacturer, EVG Entwicklungs- und Verwertungs-GmbH, located in Raaba near Graz was already able to meet this high demands to the customer‘s complete satisfaction as far as the Gunskirchen and Herzogenburg facilities were concerned; hence, the choice was not difficult this time either. The EVG project team convinced by the competent advice – the project-specific requirements were met to the full extent. Therefore, now the concept of EVG includes, among others, alternating cross wire positions without any complicated mesh turning, the production and turnout of external reinforcement or the integration of intermediate storage logistics for covering peaks in production.

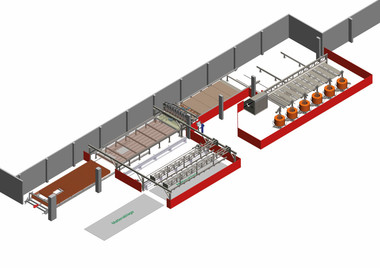

The fully automated EVG welding line of the FBE series is used

The highly flexible, fully automated welding line of the FBE series is manufacturing welded reinforcement elements of various geometries from coils directly; the connection to the customer‘s master computer ensures an automated production of the required reinforcement per pallet on time. Changeover times are not necessary for the production of different types of mesh, the welding line is operating continuously even for production batches of just one mesh sheet.

A multistrand rotor straightening and cutting machine of the RA-XE series is used for straightening and cutting of longitudinal bars and transverse bars made of hot-rolled material in a diameter range of 6 - 12 mm. The machine operates directly from coils weighting up to five tons.

The longitudinal bars are deposited in the chain magazine according to the mesh units to be produced in 50 mm grids. After filling, the bars are moved crosswise to production by means of a longitudinal bar transfer system and passed over to a welding table by means of a feeding system. The bars can be fed and positioned in the welding line individually and independent of each other.

A sectional steel conveyor is positioning the transverse bars, which are prepared for being fed into the welding line optionally beneath or above the longitudinal bars by means of manipulator and paternoster elevator. For the first time, an innovative buffer system was realized in the paternoster elevator, resulting in an enormous increase in efficiency in case of frequent diameter changes of the transverse bars. The length of transverse bars is infinitely variable starting from 35 mm.

The welding line consists of a sideways running welding portal for individually controlled welding units which are set up quickly. This enables the simultaneous welding of up to twelve welding points, along with a significantly higher production output in comparison to the competition. The otherwise usual shifting of welding units is no longer necessary, soiling of the contact areas to the collection units as well as excessive wear and tear are eliminated.

The configuration chosen here allows for the production of mesh sheets in dimensions ranging from 500 x 800 mm to 3,500 mm x 13,000 mm.

Several mesh feeders provide for the requested cross wire lengths, the feeding of the mesh sheets to the integrated line wire bending station and to the removal station. A mesh sheet crane equipped with a special gripper system ensures the fully automated take-over and transport which are integrated in the production process; all reinforcement elements of a pallet can be lifted and positioned together. In order to compensate different speeds between mesh production and pallet circulation or to prefabricate the respective reinforcement for several pallets, intermediate storage is possible in the mesh sheet magazine. In this way, flexibility and production reliability are increased even more.

Experience and quality awareness are paying off

The decades of experience of EVG as a supplier of welding lines for reinforcement mesh in a variety of models again proved to be an enormous benefit during installation as well as the initial operation in February 2020, namely during the Covid-19 lockdown. The execution of works on the construction site and the start-up of production were completed on schedule in strict compliance with all regulations in respect of the coronavirus pandemic.

Finally, it should be stated that the very low demand for spare parts and wear parts that the Gunskirchen and Herzogenburg factories are famous for as well as the known reserve capacity of the EVG production lines help to cope with the challenges of the future best possible in the long run.