Modular Housing System for earthquake-proof living space in Peru

The Reymann group of companies realized, in cooperation with the Peruvian customer Llaxta, a modular housing production system for creating cost-effective and safe living space. A visionary idea turned into an impressive housing construction project.

The vision: 300 km south of Lima, just some kilo-meters from the city center of Ica, “Las Piedras de Buenavista” is to be created – a modern and safe housing development with its own shopping mall, boulevard, lagoon, sports grounds, skatepark, school, church and 91,000 m² of green areas. The aim is to provide a high standard of living at affordable prices.

The plan: Building 3,600 houses each with three rooms, a living area of 70 m² on two floors, its own patio and garden, on a site covering 1,000,000 m² within a construction period of only 60 months. As Ica is situated in a tectonic region in earthquake zone XI, the houses have to be earthquake-proof as well as storm-proof. In parallel, the material usage is to be minimized; the structural components are to have outstanding surface qualities, eliminating elaborate finishing work, with thin-walled cross-sections. In addition, the client required a production system that ensured short construction times, efficiency and high quality.

Ratec and Reymann Technik with their know-how gained from plant design, their high-precision formwork technology and the upcrete process developed by them were able to offer the Peruvian company an appropriate solution.

The basic idea

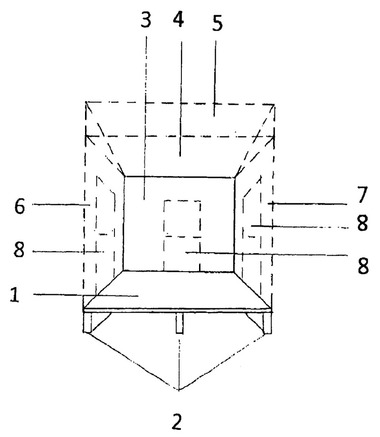

The construction system is based on manufacturing a monolithic room module, with load-bearing walls, floors, beams and electrical and sanitary installations already incorporated, being made “in one pour”. Only roof, partition walls, stairs and balconies, where required, are added, which are concreted in separate formwork for installation on the construction site.

Reymann Technik as general contractor implemented and handed over the complete, turnkey production line. Ratec manufactured and supplied all formwork and the pump technology, totaling to: three formwork units for the room modules of 3 x 6 x 3 m (W x L x H), a battery mold with six pockets of 8 x 3 m, two stair molds, two balcony molds as well as two pump cars on the basis of type UPP 100.

The production building in steel construction with dimensions of 25 x 12 x 110 m will, after all, not be demolished after the completion of the houses; it will then accommodate the community center and shopping mall of the new housing development.

Complete house in less than 48 h

Two complete houses are manufactured per day, each consisting of three room modules, six partition and exposed walls, a stair, a balcony and two roofs. All elements are manufactured in an upcrete process, which means that a rotor-type pump pressure fills the molds with self-compacting concrete (SCC) from below. In conjunction with the pressure-resistant molds specially designed for this process, upcrete allows manufacturing in installation position even with the complex geometries of the room modules, and makes vibrating compaction superfluous. The concrete is distributed completely and evenly inside the mold due to the pumping process. This ensures a structural component with the good surface quality on all sides, edge sharpness and dimensional accuracy, as requested.

For enabling production in installation position, the formwork of the room module developed by Ratec consists of an external formwork and a mold core, which is “shrunk” for removal of the mold and lifted out. After curing of the concrete, the overall width of the core can be reduced by 4 cm on the wall and 2 cm on the corners, respectively.

Surface coating and embedded parts ex factory

All preparations, such as reinforcement, fixing of embedded parts, water conduits and electricity connections are carried out on the module core, which is fixed into place in the external formwork. The closed mold is filled by means of an UPP 100 rotor-type pump (upcrete pump car) with self-compacting concrete via a concrete filling connection.

The lifting strength required for the removal of the mold is reached after 7 to 9 h. Side formwork, inner core and cover can be used immediately for concreting the next room module. Painting, sanitary installation as well as the installation of windows and doors are carried out directly at the factory in Ica. Partition walls, stairs, balconies and roofs are manufactured in parallel in appropriate formwork, while the foundations are prepared on the construction site. The complete final assembly of the houses takes place just in time on the construction site, which is possible due to optimizing all production processes as well as the site logistics in regard to the production capacity.

Conclusion and outlook

An earthquake test especially carried out at the University of Peru in Lima using a prototype house of the plant confirmed earthquake safety up to level 9 on the Richter scale. The modular construction system, moreover, provides further advantages: fewer steel reinforcement is necessary, while the overall system has a higher stability; expensive special mounting parts for the connection of different elements are not needed; expenditures for finishing works, such as pipes or cable looms are reduced, because they are positioned directly during production and there are no joints between the individual walls and between the walls and floors, respectively, thus no leakage.

The upcrete modular housing system provides a practicable, efficient solution that is unique so far, in particular, for projects like Affordable Housing and Low Cost Housing Programs. The privately owned house in Ica sold at a price of less than 25,000 US dollars is quite affordable for Peruvian standards.

The production in Ica is still running until 2018. The challenge of creating cost-effective and safe living space exists all over the world. According to the supplier, the upcrete modular housing system is clearly superior to other production methods under appropriate boundary conditions, as it is earthquake-proof, climate friendly, material efficient and economically viable. The further development of the construction and production system – for example, for other climatic conditions, more complex geometries and larger dimensions – are in progress. Furthermore, the company is already working on the further development of the modular system as well as additional production sites with the Peruvian customer.