New ConsurTest bond strength tester

The company Form + Test has further developed its time-tested ComTest automatic bond strength tester to the new ConsurTest in response to customers’ wishes. This device is compact and lighter than previous models. It is a high-precision, mobile bond strength tester, independent of mains power, for determining the surface tensile strength, adhesive strength and pull-off strength of concretes, coatings, screeds, mortars, plasters, adhesives, asphalt, parquet flooring and composite thermal insulation systems currently on the market.

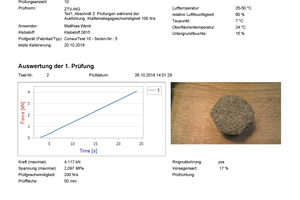

In addition to individual measurement data evaluation by using Excel files, the ConsurSoft software has now been programmed for simple preparation of test reports. General product data can be saved and the determined measured values evaluated. For every pull-off test, the system displays graphic plots for the test sequence, with load increase (N/s), test face area (e.g., diam. 50 mm), tension (MPa = N/mm²) and maximum force. The fracture pattern can be assessed based on the failure mode (cohesion or adhesion), the direction of the test and information on whether testing took place with or without a ring groove.

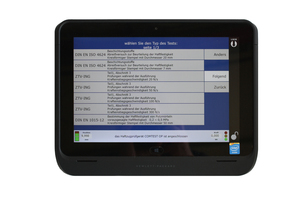

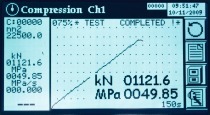

The exchange of test parameters and of the measured values is performed via Bluetooth. The operation is systematically kept very simple. It is logically organized and accordingly user-friendly. The pull-off tester (Figs. 1 and 2) consists essentially of two components: the bond strength test unit with integrated loading drive, rechargeable-battery power source, an intrinsic digital display for directly showing measurements as well as a tablet PC that contains all the test programs generates these programs and, moreover, serves as data storage.

ComTest further developed to the new ConsurTest

Currently, 18 fixed programs based on specifications are permanently stored in the device: e.g., for load increase – i.e., increased loading and size of testing stamp and area. Test programs and speeds deviating from the above can be freely selected.

The current standards include the following:

ZTV – ING for N/s – 100 N/s and 300 N/s

EN 1015-12

EN 1348 for testing stamp 50 x 50 mm

EN 1542

EN 12618-2

EN 13892-8

EN ISO 4624 for testing stamps with diam. 20 mm and 7 mm

ETAG 004 for testing stamps 50 x 50 mm and 200 x 200 mm

DIN 1048-2

Load increase takes place automatically as force (kN/sec or N/mm²/sec) or stroke control (mm/sec) with absolutely constant and shock-free load increase. Force measurement takes place by a high-precision load cell, which ensures adherence to limit values for measurement uncertainty according to DIN EN ISO 7500-1, in Class 1.

For timesaving application, the device features a quick coupler as strength plate fixture, which, in addition, features an illuminating device. This also enables work under extremely unfavorable lighting conditions such as in tunnels. Two integrated grip handles, at the left and right of the device, ensure comfortable and safe handling.

In addition, upon completion of the test, a voice memo can be recorded for the individual inspection body

This voice memo is attached to the measurement protocol and is saved. In this way, comments can be easily documented for the inspection body.

With the new construction series, and as logical extension and/or completion, fracture patterns (pull-off of the testing stamps) can be photographed and saved in the measured-data memory. Every test and every test protocol include a setpoint/actual value diagram, related to the increase of loading. The built-in battery recharger enables up to 100 tests, relative to the maximum load.

The delivery scope includes, apart from the tablet PC, two battery-charging units, a robust plastic carrying case and an official calibration certificate.