New MBH micro-batch feeder – a versatile metering tool

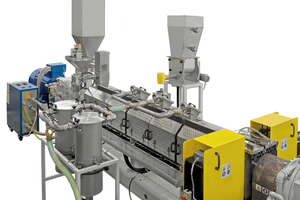

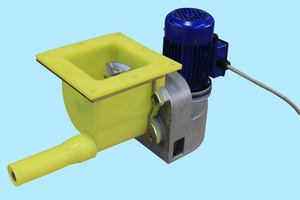

Enhanced ease of use, improved design, reduced energy consumption – according to the manufacturer’s specification, the new MBH micro-batch feeder caters to virtually all requirements and impresses as a versatile feeding and metering tool: with the new MBH, WAM has developed a compact micro-batch feeder that can be used in almost all areas of dry bulk material handling due to a wide variety of different equipment configurations and certification in accordance with EC 1935/2004 and ATEX. It ensures continuous or batch volumetric feeding of powders or granular materials required in the production of food, glass, plastics, chemicals or construction materials.

The MBH feeder is equipped with a new reduction unit that completely omits the use of oil or grease as a lubricant. Material contamination and soiling in the working environment (inside the housing), which can occur with lubricated gear units, is eliminated in the MBH feeder. A positive side effect – lubricant maintenance is no longer required. Unlike in the MBF predecessor model, a new gear unit design allows the blending and feeding screws to be driven by one instead of two motors. As a result, energy consumption is reduced by more than half, since the more powerful motor required for driving the blending screw is eliminated. An optional variable speed gear unit or frequency converter additionally allows the MBH feeder to be operated in the preferred speed range.

Additional sizes and accessories available from fall 2021

The strengths of the new compact design are fully exploited in particular when processing poorly flowing materials or materials tending to pack. Due to the seamless feeder housing and laterally installed trough with metering pipe, material residues are minimized. The blending screw, which is fitted with plowshares and inclined blades, combines effective blending and thorough discharge from the housing into the trough. This prevents caking and material bridges, ensuring direct and even feeding of the material to the metering tool. The transparent inspection hatch permits easy monitoring of the processes in the feeder and provides quick access to the inside of the housing without having to dismantle any upstream or downstream components. The standard glass-bead blasted surface can be replaced by a finish of higher quality in accordance with requirements, culminating in a mirror-polished design.

Similar to the predecessor model, multiple types of screws with different flight angles are available for the actual metering process, allowing highly accurate metering rates ranging from 0.5 dm³ to 3,000 dm³. The magnetic quick-coupling system is a new feature and enables the screws to be replaced in a matter of seconds.

For highly abrasive materials, WAM recommends to use a housing and metering pipe in wear-resistant SINT polymer design. The resilient material extends the useful life of the components and has therefore been used successfully for numerous years, for example, in auger screws, shut-off valves or pipe elbows.

The MBH micro-batch feeder is not only available in different equipment configurations but also allows accessories to be added. These include square or round hoppers, round hoppers with mixing tool, vertical feeder outlets, reed switches for cylinders, an automatic lubrication device, as well as vibrators.

The MBH feeder is currently available with square flange sizes of 26 cm and 42 cm. WAM has announced that additional sizes and accessories will be available in the fall of 2021.