New connecting rail

The new and approved Philipp Power One connection system is the consequent further development of and supplement to the Power Duo system that has been successful for more than a decade now. It is hardly possible to imagine modern precast construction without such mounting part systems with flexible wire loops, offering a wide range of applications when it comes to the connection of reinforced concrete elements.

The Power One rail comes exactly into play where the Power Duo reaches its limits – namely minor component thickness. Now, it is possible to connect thin precast elements starting from 10 cm by means of the new development without any problems.

Rail system for thin precast elements

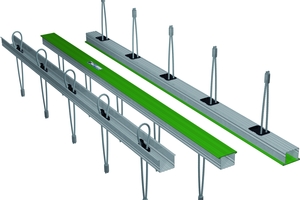

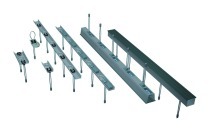

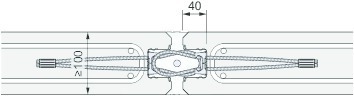

The rail system that, according to the manufacturer, is currently the only one in the world for thin precast elements consists of a pair of opposing rails featuring only „One“ rail geometry with a profile cross-section of 50 x 40 mm (width x depth). As usual, the rail comprises five wire loops at a distance of 25 cm. They are arranged symmetrically.

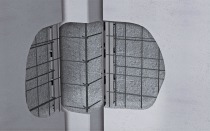

The new Power One rail, like all other rail systems made by Philipp, consists of a structured sheet metal profile. In combination with the interlocking opposing wire loops, this ensures a strong frictional connection of the steel casing with the concrete as well as the mortar core. The transfer of forces in three directions: shear forces in parallel and perpendicular to the joint as well as tensile forces at the component level are technically feasible.

The design of the Power One rail is identical to the Power Duo, hence planning is already routine. The maximum rated values of the load-bearing capacity specified with 60 kN/m for shear forces parallel and 37.5 kN/m perpendicular to the joint and a tensile force bearing capacity of 40 kN/m demonstrate the high capacity of the system.

Wall-to-wall connections

The Power One rail, that is easily distinguished from the other Philipp systems by a green cap, provides for a wide-ranging field of application as usual. The main focus of the new rail, however, is on wall-to-wall connections in various designs. Fire protection requirements can be implemented extensively, allowing the implementation of a wide variety of applications. In direct comparison to separate boxes, the new rail system is installed in a simple, quick and efficient way. The actual connection is completed by grouting the joints with the Betec grouting mortar.

Thus, the portfolio of Philipp in the field of connection technology is further rounded off, and an additional expansion of the product range can still be expected through future new developments.