New control solution for precast concrete plants

With Wavision Weckenmann has recently developed a control tool, using all data available at the precast concrete plant, which unifies administration, work preparation, production and reporting in one system. The production control system is the result of interdisciplinary collaboration of software developers and machine designers; the findings of customer surveys were also taken into account in the development.

Wavision becomes the central interface of data available at the company, it “translates” CAD data and provides the individual process stations with the same. In addition to that, the system optimizes the data, material and work flow, takes over storage location management, reporting, malfunction evaluation and monitors service and maintenance. Thus, the control system developed together with experts of Granilt GmbH is an omniscient coordinator between order, machine and production; it consists of modules that can be selected and used as a total package or separately, depending on the requirements. Several customers in Russia, Kazakhstan and even the U.S.A. are already successfully using Wavision that is available with various modules.

Central ProductionManager

The ProductionManager as a central authority for administration and control of the production plant verifies the geometric data of the concrete element and prepares them for the production. In this process, the DXF CAD data are converted to the current UT 6.0 data format. The dimensions can be transferred at a scale of 1:1 or according to a specially defined scale; in addition, the units of measurement can easily be converted from the metric system to the imperial system. The CPO (cleaning, plotting, oiling) station is equipped with a spraying unit that automatically sprays retarding agent on the pallets according to the CAD data. The different final products to be manufactured are moreover recorded in the program together with their particular properties. The ProductionManager also controls the specified production sequences.

ProductionControl, WebInfo and WebFlow

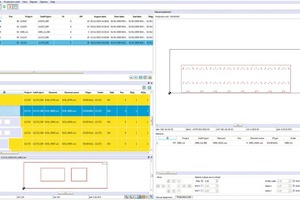

The ProductionControl unit basically controls the pallet movements. Pallet assignment and production process are visible at glance through the visualization of ProductionControl. Moreover, the work sheets needed for the production, such as configuration sheets or labels, are printed automatically. This unit also provides the data for the plotter or the formwork robot and transfers the production data to the circulation control system.

The visualization from the WebInfo module can be called up irrespective of the operating system by means of any popular browser; this means that the visualization works on every PC and all mobile devices such as tablets and smartphones. The user can call up information on circulation positions and their assignment, on all plant components and control points, assignment overview and status in the curing chamber, operation of the heating control system, display of the temperature curve and possibilities for manual intervention, display of message texts and malfunctions.

Further module options are WebFlow, allowing the visualization of the pallet circulation or the plant, and the Reports software element for customer-specific work reports. The ReportDesigner has access to all database tables of the Wavision system; the StorageMaster enables efficient storage location management using barcodes and RFID.

Nominated for Bauma Innovation Award

Weckenmann has already been nominated for the Bauma Innovation Award 2016 in January. Klaus Dittrich, CEO of Messe München, announced the 15 nominated companies and their innovations selected among the overall 118 applications from Germany and abroad. The jury has now chosen three new developments in each category to go forward to the final round. All of the innovations nominated are sustainable and economic developments providing a considerable practical benefit, and they make a contribution towards energy- and resource-efficiency and/or towards the humanization of the workplace.

Weckenmann has been nominated in the category of machinery with the mobile battery mold (MBM/see also BFT 3/2016 p. 26 ff.).