New data standard for the precast concrete industry

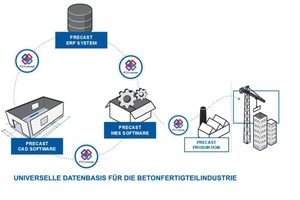

At the beginning of last year, acting on the initiative of FDU, all major CAD- and MES-based software developers formed their own industry-wide working group with the objective of creating a uniform basis for process optimization and information distribution for the entire precast concrete industry. The required data structure, as well as a definition of standards, were created in several expert groups under the sponsorship of BuildingSmart.

First precast-specific data format

The new IFC4precast interface contains, as the very first precast-specific data format, all 3D model information, including complete geometries. In addition, and also for the first time, an unambiguous allocation of precast parts is now possible.

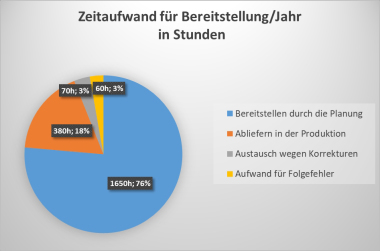

The three speakers of the working groups – Benno Strack (FDU), Werner Maresch (Precast Software Engineering), and Stefan Maier (RIB SAA Software Engineering) – can now present the first successfully completed testing mode. FDU was able to manufacture the first precast floor slabs and double walls in several locations, independently of the software, on the basis of the new IFC4 data standard. Benno Strack, Head of MES Process Control Engineering at FDU, describes the essential benefits as follows: “The new IFC4precast interface will enable us to achieve considerable savings throughout the entire planning and production proc-ess.”

“The new IFC4precast database will forever make interface problems caused by different data formats and plant-specific configurations a thing of the past,” says with satisfaction Werner Maresch, Managing Director of Precast Software Engineering GmbH. He continues: “Complete and detailed transmission of geometric information means that IFC4precast provides the basis for more effective data exchange in the precast concrete industry. IFC4precast thereby guarantees highest quality data exchange between the different IT systems – in the future as well – according to the motto: Not only anticipating the future, but also making it possible.

Stefan Maier, Vice-President of RIB SAA Software Engineering adds: “The objective is to support the flow of thoughts and data for the advanced OpenBIM, for which currently applied interfaces place limits. This support likewise benefits planning and production in precast plants. Greater data content in the future will enable the MES system still more enhanced optimization and efficiency increases in production.”

Results presented at Engineering Days

In late November this year in Vienna, Engineering Days, the technical congress for the precast concrete industry, presented the results of its working group and reported on experience gained from initial successful testing operations at FDU. However, from implementation of the new data format in the respective user interfaces for planning and production, the working group still has a long way to go. The next planned step, in addition to ongoing development of the interface, is to enlarge the expert group by including ERP system developers.

The company members of the committee are: RIB SAA Software Engineering GmbH, BWB Beteiligungsgesellschaft mbH & Co. KG, Precast Software Engineering GmbH, IDAT GmbH, Progress Group GmbH, Unitechnik Systems GmbH, AEC 3 Deutschland GmbH, and Trimble.