New design and management methods for fresh concrete properties

Nowadays, concrete mix design and production almost exclusively rely on deterministic approaches. This means that the mix design process fails to take account of fluctuations in the properties of raw materials; nor does it consider variations during production and casting. Likewise, no adequate approach has yet been developed for accurately and reliably responding to such variations already during the concrete production process, and for managing and adjusting the mix accordingly. The research presented in this paper focuses on techniques capable of capturing the material properties as early as at the production and transport stages (for instance during the mixing process), as well as on self-learning models and software algorithms that alter the concrete mix by including additives in the design (Approach 1). At the same time, this research attempts to develop methods for implementing a statistics-based mix design process (Approach 2).

Approach 1: Active safety and reliability by management and control

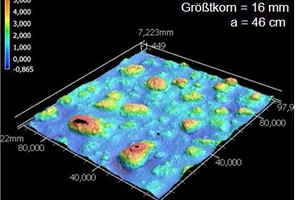

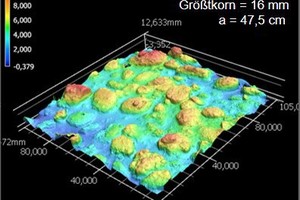

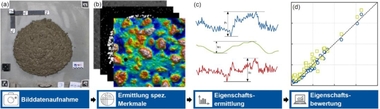

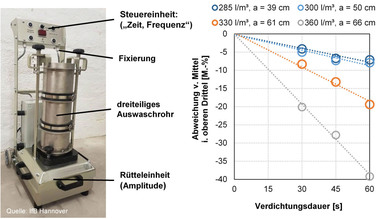

The concrete production process in the precast industry is characterized by an extremely high degree of repetition, which is why this industry is perfectly suited to applying methods based on artificial intelligence (AI). However, such methods require an extremely large database that is, ideally, continuously updated in real time. Yet we are still lacking methods for capturing the properties of the concrete during its production and to manage and control them as and when required. This is why the Institute of Construction Materials at Leibniz University Hanover has partnered with an industry consortium to jointly develop sensor systems that capture the properties of (fresh) concrete basically in real time. The data gathered in this process is then fed into a self-learning algorithm determining the ratios of the mix constituents with the aim of adjusting the mix to specified target values. The described measurement methods can also be used for monitoring the (fresh) concrete properties on the construction site (see fig.), and can thus be seamlessly integrated into a Building Information Modeling environment.

Approach 2: Passive safety and reliability by robustness

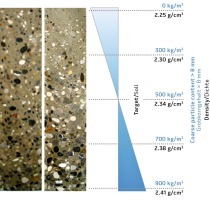

The mix design process should aim to utilize the previously recorded variation patterns in order to identify the mix composition that provides the highest possible robustness in responding to expected variations while still ensuring the specified characteristics in terms of slump flow, strength etc. According to this approach, the robustness of the concrete (i.e. the coefficient of variation, for instance in relation to slump) is determined already at the mix design stage, rather than having to conduct comprehensive analyses in order to quantify the interactions between fluctuating parameters as part of the initial testing program.

This paper provides a brief overview of both approaches based on methods of statistics-based mix design and principles of artificial intelligence, which are, however, combined with the laws of physics.

research presented in this paper.

Co-authors: T. Schack, D. Beyer, Jack S. Moffatt,

C. Begemann