Stability of modern concrete

Background

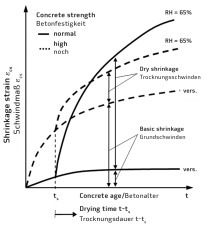

The notion of “modern” or contemporary concretes is used as a reference to concretes with relevant PCE-based plasticizer ratios. Nowadays, such types of concrete are used not only for high-performance mixes but also, to an increasing extent, for “standard” concretes in structural engineering, including bridges, locks, wastewater treatment plants, industrial floors and other structural components. These types of concrete ensure enhanced fresh concrete properties, such as a softer consistency, but also very low water contents particularly for bulk or green concrete. The high amount of PCE-based plasticizers also leads to a higher sensitivity of the fresh concrete to the added water quantity or the intensity of compaction, which inevitably increases the risk of segregation. Ensuring the stability of the mix while subjected to vibration is thus crucial in contemporary, sustainable concrete construction. This paper discusses the related requirements and actions to be implemented.

Concrete mix design

To ensure a sufficiently high stability of the mix during concrete pouring even under difficult conditions, a number of questions need to be answered as early as at the concrete mix design stage:

Are additional aggregate sizes (such as fine sands) or further admixtures (such as limestone dust) or additives (such as stabilizers) needed to enhance mix stability?

At which level should the paste ratio be set to strike a balance between adhering to (controversial) minimum paste ratios (cf. the BBQ – BetonBauQualität; Concrete Construction Quality – guideline) and preventing deleterious excess paste content?

How should the paste ratio, paste viscosity and compaction intensity be adjusted to each other so that the concrete can be poured safely while avoiding defects and deficiencies?

How can mix stability and robustness be taken into account at the same time?

Test methods

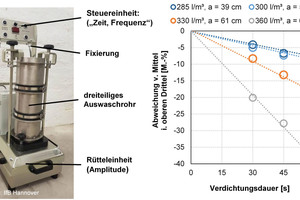

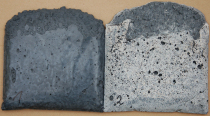

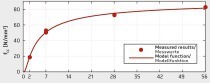

Answering the above questions requires a reliable, reproducible test method for determining the stability of the mix subjected to vibration. The sedimentation behavior of concrete is difficult to determine during vibratory compaction because the vibrational energy introduced into the concrete should be both reproducible and representative of the structural component to be produced after the test. This is why a test method is currently being developed and trialed in a collaborative research project together with Ruhr University Bochum (Prof. Breitenbücher) and the Federal Waterways Engineering and Research Institute. The test results can be analyzed with respect to a sedimentation resistance that would be characteristic of the investigated concrete. This characteristic resistance value can then be used, for instance, for adjusting the duration and intensity of compaction during concrete pouring to the relevant mix stability (Fig.).

Acknowledgements

The authors thank Deutscher Beton- und Bautechnik-Verein E. V., Bundesverband der Deutschen Transportbetonindustrie e. V. (German Ready-Mixed Concrete Association) and Bundesanstalt für Wasserbau (Federal Waterways Engineering and Research Institute) for funding part of this research.