New era in the production of piles at Skanska

Skanska Sverige AB with its headquarters in Bollebygd, Sweden, has made a name for itself in Sweden as a producer of driven piles. As an innovative company, the implementation of fully automated driven pile production, realized in collaboration with the mbk represen-tative for all Nordic Countries, Mikael Lundell from Semtu and mbk Maschinenbau GmbH from Kisslegg, is now pending.

Skanska‘s focus was on high automation on the complete handling of the reinforcement rods fed in through to the finished cage – including further processing of the formworks. The bar was exceptionally high: with approx. 1,000 running m per shift, just two operators had to satisfy the requirements profile.

Automated longitudinal wire feed

For mbk this was no unattainable goal: much higher metre numbers had previously been achieved in similar tasks. With almost 1,000 machines around the world, mbk Maschinenbau GmbH is well positioned in the concrete pipe and construction industries. Welding machines for the reinforcement of concrete pipes and shafts have been being produced in Kisslegg since 1961. Around 15 years ago, mbk started to secure the construction industry market segment as well and, since then, has been producing welding machines for round, square, round edged, oval and conical cages for supports, masts, piles, foundation piles, beams, etc. In addition, multiple mesh welding machines favourably support day-to-day production for some prefab manufacturers.

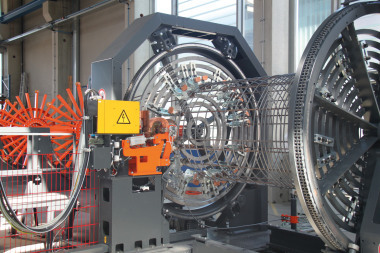

VSM is time-tested and has more than proven itself in the production process. A modification was now envisaged with the aim of automating the longitudinal wire feed using a chain conveyor. The rods are thus isolated using a wire straightening and cutting unit and fed into the chain magazine. After each rod, cycling on occurs automatically thus also allowing different diameters to be processed alternately. Before the VSM, there is a longitudinal wire magazine. This longitudinal wire magazine takes single or double wires at four corner positions. After approval from the control system, the chain conveyor loads the four or eight rods into the magazine, which turns automatically. All rods are thus fed into the VSM at the same time.

Tight winding and with the largest possible gradient

An interconnected feed unit makes the simultaneous production of tighter winding at the start of each cage with a max. 15 to 20 mm protrusion of the longitudinal wire possible. On a VMS, longitudinal wires of 8 to 20 mm as well as double wires of 12 to 16 mm can be welded into cages with winding wires of between 5 and 8 mm.

At Skanska, wires with diameters of 12 to 14 mm and 16 mm are used as individual wires and in combination, and 20 mm diameter wire is also used as individual wires. The VSM welds the winding wire onto the longitudinal wires fed into the machine at up to 50 RPM. Cage production can thus be realized in the impressive sizes of between 92 x 92 mm and 375 x 375 mm in lengths of up to 14,000 mm. Each cage requires tight winding at both ends, while for the rest it is practical to operate with the largest possible gradient. The electronic controls of the VSM performs this task as a fully automated function. In order to maximize the added values, it is wise to fully exploit the system‘s performance potential. The automatic unloading of the cage and its removal from the cage processing system, which allow for fitting with spaces, ensure rationality and thus efficiency.

Up to 1,200 cages with double rods in 8 hours

Once the safety sector approves the cage, the processing system automatically places it on a chain conveyor from which the cages are positioned, in bundles, in a store using a special crane.

For Skanska, it was very important to find a partner who was able to ensure compliance with the precise tolerances for these exacting products. Several parameters needed to be taken into account here, such as the precise position of the longitudinal wires, the straightness of the winding wire and the smallest possible amount of twisting of the cages. If all of these considerations are satisfied, then production with optimal concrete cover is ensured at Skanska.

With mbk, Skanska found a partner who was able to satisfy all requirements profiles and increase the output to the agreed production quantities in the shortest time possible. The partnership-based collaboration made it clear once again what enormous potential is released through this kinds of alliance: the extremely precise and highly productive welding process, in combination with the special application software, represents an absolute improvement in day to day production. Thus the production of 1,000 to 1,200 cages with double rods in an 8 hour shift can be considered as normal.

For mbk, customer focus and service awareness do not end after delivery – after-sales service plays an important role in day to day business. Fredrik Andersson from Skanska can confirm that.

With the use of VSM from mbk, Skanska entered a new era in pile production. An era in which production processes ensure the greatest degree of efficiency, which is ultimately beneficial for everyone involved. The customer most of all, of course.