New packaging system for concrete drainage channels

In 2019, Keller looks back on a successful company history of 125 years. In the beginning, the focus was exclusively on solutions for the heavy clay industry, but in the meantime, projects with concrete products have also been successfully completed. Here, Keller relies on robot and automation technologies, making production and logistics processes more productive, more efficient and more flexible.

For example, the division Intelligent Machinery Solutions (IMS) has developed a tailor-made packaging system with industrial robots. The task was to design a system for concrete drainage channels to be taken-off from an existing conveyor system and which are then to be stacked on pallets according to different setting patterns. At the end of the process, the packs are strapped, transferred to a forklift truck and stored intermediately.

Technical requirements

The drainage channels of the German producer Birco vary in their dimensions from 160 to 560 mm wide, 510 to 1,020 mm long and 80 or 550 mm high. Their weight is between 17.5 and 314 kg each. Some drainage channels have gradients of up to 5 to 10 mm over the channel length. To avoid misalignment of shipping packs, which may result from the amount of gradients, the shipping pack must be turned by 180° after each layer.

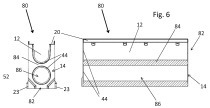

The transfer gripper delivers the drainage channels to special wooden boards. Depending on the format, up to four channels are on a board, with the open side to the top. The transfer gripper picks up the entire layer in one cycle and passes it to a toothed belt conveyor. Since the gripper can be positioned directly above the take-up position with still incoming channels, a very short cycle time is achieved.

After successful quality control, the drainage channels are released by the machine operator for palletizing. The robot deposits the waste channels with or without reinforcement on two separate lines in order to dispose of them in an environmentally friendly way.

Plant description

The task of palletizing is shared by two 6-axis industrial robots. The handling of the drainage channels is assumed by the first palletizing robot whose gripper can transfer up to three channels simultaneously. On the pallet, the drainage channels can either be stacked lengthwise or crosswise to the transport direction. In case of channels, which have gradient, the pallet is turned by 180° after each layer. For many formats the robot deposits the top layer with the opening downwards, so that the finished packs can be strapped. The robot detects height differences and compensates them during stacking. Depending on the format, the package can have up to seven layers.

The gripping system of the second palletizing robot serving as empty pallet gripper with 4-row suction device has two functions: Positioning of empty pallets on the turntable and placing wooden strips between each layer.

On a chain conveyor, the stacked packs are conveyed to the strapping equipment. Before strapping, the pack is passed to a further chain conveyor, which is located on a carriage. This chain conveyor can be turned to perform longitudinal or transverse strapping in only one position.

The strapped packs are finally transferred to a second identical carriage. This carriage moves to two magazine chains, is turned by 90° and delivers the packs. The pallets are always transported in longitudinal direction, so that at the end of the chain conveyor a forklift truck picks up the dispatch packs and conveys them to the stock.