Next-generation production board presented

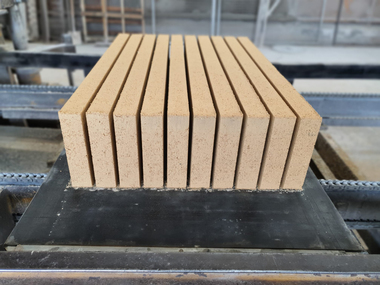

The new UPadvanced production board (protected by Patent DE202015102814) impressively combines the benefits of wood and plastic. It comprises a wooden core and a full plastic cover at its top and bottom.

The wooden core developed specifically for this new production board excels with its outstanding structural characteristics and low weight. The plastic cover ensures exceedingly smooth block undersides while also allowing effortless production of large blocks or slabs. According to the manufacturer, the board’s modulus of elasticity of 12,700 N/mm² is very good.

Other advantages include a jointless surface, less surface wear, elimination of draw plates, the board’s low weight, the use of predominantly vertical-grained planks (lending superior structural properties to the product), shorter cycle times, and unrivaled value for money.

For interested visitors of this year’s bauma trade show, MyWood will be showcasing sample boards for testing at its stand B1.415.