“One step closer to the future”

Chemical engineer Fulvio Canonico has been managing Wilhelm Dyckerhoff Institute for Building Materials Technology since early in 2017. The WDI is responsible for the entire research and development of the cement manufacturer – and together with the laboratory in Trino, Italy, also for R&D projects of the Dyckerhoff parent company Buzzi Unicem. The editorial department of the technical journal BFT International met in Wiesbaden with Canonico, Dr. rer. nat. Dieter Israel, head of the WDI subdivision “Laboratory Operations”, and with Graduate Civil Engineer Graduate Industrial Engineer Martin Möllmann, Head Marketing and Head White Cement Sales, and spoke with the managers about new markets for cement and precast concrete manufacturers, Dyckerhoff’s client-oriented applications consulting and why the cements of the company located in Wiesbaden take you “One step closer to the future”.

BFT International: Mr. Canonico, belated congratulations on your promotion to the head of the Wilhelm Dyckerhoff Institute.

Canonico: Thank you.

BFT International: Prior to your promotion you already headed one of three subdivisions in the WDI, namely the subdivision “Research Binders and Concrete”, as well as the research of the Dyckerhoff parent company Buzzi Unicem in this area, across Germany and Italy. Will you make use of this experience and concentrate the research efforts of the national branches of the group more closely across countries?

Canonico: Prior to my appointment I spent 50% of my time in Germany and 50% of my time in Italy working in this field. This is one example of the close international cooperation within the Buzzi Unicem group.

Already in 2015 the group organizationally coupled the activities of the two laboratories, the WDI here in Wiesbaden and the laboratory in Trino, Italy.

In addition, as is the case in any group, there are meetings on different organizational levels on a regular basis. Every two years executives from the subsidiaries, e.g. from the Netherlands, from Luxembourg, Italy and Germany, meet and exchange ideas. The last meeting was held in Hirschhagen, Germany in October of 2016. The first day there we visited a tunnel construction site. The next day the individual countries gave brief presentations about what was happening in the Netherlands, in Luxembourg, in Italy, in Germany and so on. At these meetings literally everybody gets a chance to speak. We want to strengthen the exchange of ideas and opinions through these meetings.

Thus, within the group there has always been a lively exchange in the area of research and development.

BFT International: This exchange is presumably quite useful – the market is extremely competitive and every idea, every improvement or new development could mean a critical advantage?

Möllmann: Right. In the European countries the cement sales figures have either been consistently level for years or have even gone down. Overall we live – thank God – in a very peaceful region that is spared from natural disasters too; however the result is that construction activities are limited. Thus, only by trend setting and changing settings can we stimulate construction activities.

BFT International: One trend, which comes from the political areas, is CO2 reduction. What is Dyckerhoff doing in this area?

Canonico: CO2 reduction has been a main focus of our research for some time now. We are working on different levels: In the short term we are promoting the efficiency of our cement plants and placing greater emphasis on alternative fuels. We are continually optimizing the clinker factor in our products. In the coming years the standards will enable us to further reduce the clinker content.

In the medium term we are also attempting to develop new products. Dyckerhoff has important know how about Ultra High Performance Concrete or UHPC. For a long time now we have been working on the optimization of the microstructure, of the packing density in the combination of different binders. Nanodur and all premium cements are based on Mikrodur technology. With UHPC technology and with these cements it is possible to lower CO2 levels. In UHPC we have much greater performance and strength than is the case with conventional concrete, so that it is possible to build with significantly lower concrete volumes. They save material and hence also CO2.

Möllmann: This is also a topic for the current housing shortage. The only way we can eliminate this problem in the large cities is by building more compactly, going into the courtyards and backyards and increasing the cubic volume. And this can be done especially well using high performance construction materials, taking UHPC as an example – in such cases you no longer have to build pillars with a diameter of 70 cm for example, but rather with a diameter of 40 cm and thereby increasing the net floor areas.

BFT International: You’re not the only company that sells UHPC. How does your product differ from that of the competition?

Canonico: Generally, silica fume is necessary for manufacturing UHPC, which the manufacturers in the concrete and precast plants have to add. Dyckerhoff Nanodur in contrast can be purchased as a compound. It is ready made, like a cake mix, and the manufacturers no longer have to add silica fume to it.

We can offer Nanodur as a compound because already in 1993 we built a heavy duty sifter in our plant in Neuwied, with which we can sift cement particles from 6 µm and downward.

With the Nanodur compound manufacturers can produce consistent quality robustly and without fluctuations, right in the concrete or precast plant. The compound is the best way to control quality and costs.

BFT International: Mr. Canonico, you published a scientific contribution yourself some time ago in BFT International about calcium sulfoaluminate cements. Using CSA cements is another way to save CO2. What is Dyckerhoff doing in this area?

Canonico: We have a great deal of experience with calcium sulfoaluminate cements. We have been producing CSA cements for many years, in the USA since the 1990s and also in Italy since the start of the new millennium. In comparison to conventional Portland cements, with CSA cements you can save between 25 % and 30 % of the CO2 – a portion of the reduction is due to the raw materials, since you use less limestone for the manufacturing; another part has to do with the manufacturing process itself, which requires less energy.

We are acting on the assumption that the CSA cements have potential and will allow for different applications in the future. Of course, they are more expensive than conventional Portland cement. And thus, the CSA cements will not replace the Portland cements in bulk.

There are another two areas where we are conducting research on CO2 reduction which I would like to mention: We are also conducting research on active Belite cement. Belite cement has been around since the turn of the century. However, thus far it has not been possible to achieve sufficient early strength. Belite cements cure quite slowly and this is not appropriate for today’s applications. Thus, the challenge is to develop a Belite cement that is as active as Portland cement. According to expectations, the CO2-savings potential of Belite cement is between 15 % and 20 % compared to Portland cement.

And finally, we are cooperating with the European Cement Research Academy, ECRA, and with the German Cement Works Association, VDZ, on projects for CO2 storage and CO2 recycling, as occurs in the case of the Oxyfuel process (combustion method which is ideal for power plant processes and is currently being intensively developed around the world, Editor’s note) or for post combustion technology (permanent underground storage, Editor’s note). Finally, in October of 2017 we started a new R&D project in this area with an EU partner; in the so-called Cleanker Project we are doing research on capture of CO2 with calcium-looping technology.

BFT International: You are also involved in another future project, the C3 Project – carbon concrete composite. This revolves around the new material composite of Carbon reinforcement and high performance concrete. At the end of 2016 C3 was awarded the Future Prize by the German Federal President. Carbon concrete enables manufacturers to build slimmer and thus save CO2.

Canonico: Oh yes, we are participating in this research. In principle, the material composite has some advantages; above all the durability of the concrete would be significantly increased, since the plastic reinforcement doesn’t corrode.

Within the scope of the project we are attempting to improve our UHPC and optimally coordinate the concrete matrix with the carbon reinforcement, so that the best compound results.

The C3 project is very interesting. However, a great deal is still a long way off, since currently carbon reinforcement is still quite expensive; precisely due to this reason of economy we are also investigating the use of glass fiber reinforced plastic, GFRP, as reinforcement in the concrete.

BFT International: Certainly, the use of carbon reinforcement is still a key issue of the future in many areas of the precast concrete industry. Nevertheless, you are involved in the search for future technologies.

Möllmann: That’s why at events I always say that Dyckerhoff is a step closer to the future than the others. But seriously: Dyckerhoff is a company with a strong commitment to further development in construction.

BFT International: Basic research is one task of the WDI. Another task, at least as important is offering support to your customers. Which service does the WDI offer to precast concrete manufacturers?

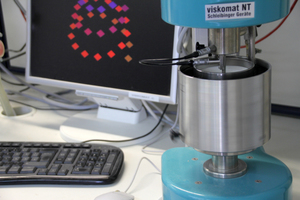

Möllmann: The WDI is a type of service provider for sales sectors of the concrete and cement organization and supports the building consultants in their work with clients. One example: A client previously bought cement from a competitor, but wants to work with Dyckerhoff now. First of course he wants to be sure that our cement will work for his products. So he wants to have proof that the strengths, the flexural tension values, the freeze/thaw values are adequate. The WDI as an authorized, certified test body for all types of concretes and mortars can perform the necessary tests and provide the client with proof.

Another example: A client has developed a new product and is not sure whether the technical parameters are in order – how about the surface, the frictional wear? Then the WDI offers tests that the building consultant provides to the client free of charge.

BFT International: How are inquiries submitted to your institute?

Israel: It takes place via the building consultants, who support and advise the prefabricated concrete plants. Then we get together here in the WDI and discuss which services must be performed, which experiments are necessary. The building consultants provide feedback to the client about the results of the tests.

However, we can also perform field trials or larger experiments here in the WDI, to which we can then invite the clients. For example, they can cooperate in the development of a formula right here in the institute. We can also set up experimental sites and try out special applications for the respective client.

BFT International: Mr. Canonico, Dr. Israel, Mr. Möllmann, thank you for the interview!

Interview: Christian Jahn, M. A.