Ongoing innovation for Australian market

Westbuild is an independent, family-owned company based in Perth and a proud supplier of packaged building products to Western Australia for over 35 years. Westbuild aims to meet and exceed standard performance requirements for Australian building products and packaged building supplies by continually reinvesting in product development and world-leading manufacturing processes.

This innovation and an ongoing commitment to our product offering has seen Westbuild introduce better packaging, being the first company to introduce rainproof bags into the Australian marketplace for packaged building products.

Whether it be setting a post in high-strength concrete, levelling or repairing a floor, or installing premium stone or porcelain tiles, Westbuild can offer a diverse and innovative product range of quality dry-mix and packaged building supplies all over Australia.

Westbuild boasts the widest range of easy-to-use dry-mix products, as well as building, landscaping and DIY products:

Dry-mix concretes and building mortars;

Tile adhesives, flexible and architectural grouts;

Floor levelling and screeding products;

Repair mortars and compounds;

Waterproofing;

Primers, modifiers and extensions.

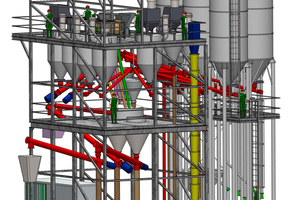

Impressive batch plant set-up

Perth based construction material supplier Westbuild is one example of an Australian company that has benefited from MCT Italy’s technology. The company purchased a fully customized dry batch plant and form fill and seal machinery which allowed them to replace traditional paper cement bags with rainproof plastic ones.The total number of components which can be stored, dosed and mixed is absolutely impressive:

6 Additive hoppers with automatic bag openers (example of components: hydrated lime, carbonate, rubber crumb, re-dispersible powder),

5 Silos (sands, middle slag, creme HE, ultra-light creme),

4 Micro-dosing systems for colored powders,

3 Hoppers for manual addition.

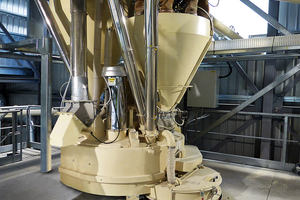

The tower plant also includes a high-speed mixer 1080 / 750 with double discharge gate for feeding of 2 bagging line: it can guarantee an hourly production of 15 tons/hour.

Westbuild’s production plant is a newly commissioned, modern facility with a high level of industrial intelligence and a high capacity to cater for private label and branded contract packaging partners. The system can dose, batch and mix up to 800 bags (from 5kg up to 30kg bags) per hour and includes a single screw weigher and palletizer.

Industrial intelligence

The high level of industrial intelligence, supplied by MCT Italy software named Compunet, is the guarantee for an assured confidentiality: most of the customers and partners do not want to reveal the mix design, thus they are protected by non-disclosure agreements which proves Westbuild’s excellence in security and privacy.

MCT Italy integrated automation allows Westbuild to constantly check the report, to store data collected on receipt of raw materials, to control production data and final bagging control. The automation control generated reports will be available to Westbuild Quality Department at the finalization of each production cycle. In details the services guaranteed are:

Westbuild remote-monitoring service,

Automatic date stamping and batch numbers,

Computerized batch records,

Physical samples from each batch, as required.

Top support from MCT Italy

Mr. Marcus Parlapiano founder’s son, adds that the flexibility to allow different mix designs to be handled with all settings changed automatically has saved a significant amount of time on short job runs as well.

“The teleservice gives us the reassurance that MCT Italy’s technicians in Italy can resolve any small problems quickly. The line was delivered on time and it was installed and commissioned without any problems. We expected a lot from MCT Italy and we haven‘t been disappointed.”

Re-investment in production

Mr. Tony Parlapiano, founder and owner at Westbuild affirmed: “It is re-investment in production that ensures we supply to the market at the best possible price”.

Not only is efficient manufacturing important to Westbuild, but so is the efficiency and quality of the packaging we use to distribute, market and present the products. “We constantly work with our supply partners to ensure our products are packaged well whilst also working towards increasing recycled material content, down gauging and all the while sustaining stronger and more flexible solutions”.

Mr. Falchetti Gabriele, Australia Sales Director, affirmed: “We have been called upon to manufacture a fully customized plant with impressive level of automation. With our modern and efficient solutions, we are proud to be the ‘manufacturing arm’ for our clients who demand strict, accurate and consistent production facilities. This is a clear example of world-class practice meeting local knowledge“.