Organic admixture for reinforcement protection in

concrete structures

Cortec Corporation is proud to announce that its MCI-2005 is the first biobased, organic corrosion inhibiting concrete admixture that passes the ASTM G180 protocol under ISO 17025 accredited testing.

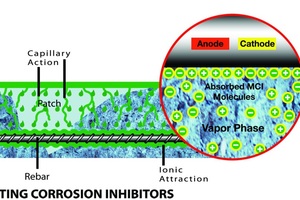

Without a doubt, durability of concrete structures is one of the biggest issues concerning engineers today. This unfortunately has been evidenced in recent tragedies such as the collapse of a residential building in Florida and the Morandi bridge in Italy. Maintenance and structural durability are essential to avoid fatal accidents like these. Durability can be greatly extended with a careful technical approach whether dealing with new or existing construction. Corrosion is the deterioration of materials over time. It is a serious problem for engineers who use metal products in their structures because it can be a major safety hazard. Corrosion of metal reinforcement is a critical risk factor for the durability of structures, and as such, the development and selection of corrosion inhibiting admixtures has to be taken seriously. One of the most efficient methods to extend service life of structures is by using MCI Technology, which has proven efficiency even in severely corrosive environments. Structures protected with MCI will have a stronger resistance to corrosion and therefore longer durability, according to the supplier.

MCI-2005 is an organic, biobased corrosion inhibitor for protection of metallic reinforcement in concrete structures. It contains a blend of amine salts of carboxylic acids. Unlike calcium nitrite admixtures, which have a set accelerating effect that can send workers scrambling or cause early setup problems, MCI-2005 delays set time, making the concrete easier to work with and reducing the heat of hydration. Other advantages are that MCI-2005 contains 67% USDA certified biobased content and is certified to meet ANSI/NSF Standard 61 for use in large potable water structures.

MCI-2005 successfully passed ASTM G180 testing

Cortec Laboratories conducted ASTM G180, one of two corrosion performance tests specified in ASTM C1582, Standard Specification for Admixtures to Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concrete. This testing method is used to ensure admixtures measure up to widely accepted industry standards for the selection and qualification of corrosion inhibiting admixtures. Cortec laboratories provided the testing through its independent ISO 17025 accreditation. This test is important for a variety of reasons as it measures corrosion inhibition ability in chloride environments.

Manufacturers use it to screen new chemistry formulations for their potential as corrosion inhibiting admixtures. Chemistries that pass ASTM G180 testing, which is conducted over the course of three days, have a strong vote of confidence for their corrosion inhibiting ability; whereas those that do not pass this quick test must undergo years of additional testing under ASTM G109. ASTM G180 is needed for quality assurance of existing products or as part of an audit like the one recently performed by Cortec Laboratories on MCI-2005 for Cortec Middle East and Dubai Municipality. Finally, ASTM G180 testing is also critical for engineers working with DOTs who require corrosion inhibitors to pass ASTM C1582 before use on their projects.