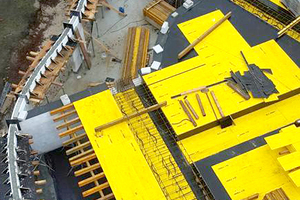

Organic shapes easily formed with Syflex

A formwork system was sought for the construction of a residential and commercial building with a demanding architecture in Ahlbeck, only a few paces away from the Baltic Sea. A lot of formwork systems are available on the market, but this building project is characterized by an extraordinary shape of the building structure. There are hardly any corners; the outer shell meanders in curves around the building structure. A flexible, reusable formwork for the foundation slab, circular beam, floor slabs, and balcony slabs was looked for accordingly.

Conventional formwork systems made from wood, steel, or prefabricated modules are often not flexible enough, are extensive in labor or cost-intensive, according to the manufacturer. A particularly effective solution for this problem is called Syflex. Therefore, the building contractor Reca Bauplan & Projektentwicklung GmbH decided in favor of this formwork system.

Easy assembling and subsequent alignment

Syflex is very easy to assemble. After installing the bracing (soil nails, formwork supports or boards), Synflex formwork profiles are simply leaned against the bracing and fastened to it using an eccentric. Syflex adapts to any curve, even up to radiuses of 2 m. The formwork boards with a length of 5 m can be connected to each other for any length.

Even subsequent alignment of the upper edge of the formwork is easily possible by simply loosening the eccentric, levelling the element, and then tightening the eccentric again. The Synflex formwork widely bends back to its initial shape after stripping due to the memory effect of the formwork boards made of a special PE compound.

The formwork is only weighing one-third of comparable conventional wooden formwork, hence allowing handling even without a crane. In Ahlbeck Syflex was also suited as formwork for lintels and circular beams. The result is a high-quality and exciting building.