Building material for

demanding building construction

The 18th Holcim Concrete Conference hosted at ETH Zurich dealt with the new challenges in concrete construction such as high-strength columns, modular construction systems as well as slender and prestressed structures. Concrete even meets the highest requirements in demanding building construction by means of sophisticated mixtures, new kinds of materials and project-specific properties.

The most important amendments to concrete standards concerning dimensioning, execution, building materials, testing and maintenance as well as codes of practice about rust-proof reinforcing steels, recycling concrete and AAR. At present, working groups are set up for the revision and amendment regarding fire, minimum reinforcement and fatigue as well as prefabrication, fiber-reinforced concrete and fastening systems.

Skeleton for the tallest building in Switzerland

The supporting structure of the tallest high-rise building in Switzerland, the recently completed Prime Tower in Zurich - being 126 m high with 36 stories (228,000 m³ enclosed space) - is a concrete skeleton structure. The cast-in-situ concrete floor slabs in thicknesses of 25 and 28 cm, which are fixed to the center core, span 7.5 and 9.5 m to the façade columns that are made of high-strength concrete with a high degree of reinforcement. The fact that the core walls made of cast-in-situ concrete shrink and creep more than the precast columns was taken into account in the design of the 2.2 m thick ground slab situated at 80 concrete piles.

The external characteristic of the tower is the green shining glass façade (21,000 m²). The extensive and groundbreaking sustainability of the tower has been awarded with the international quality label LEED Gold (Leadership in Energy and Environmental Design).

Construction within the building stock is of great importance nowadays aiming at an increased service life in the sense of sustainability and conservation of the structural value. Textile-reinforced shotcrete proved itself for repair and stabilization of reinforced concrete structures. The textile reinforcement is not sensitive to corrosion and just needs a covering of 3 mm. Spray shadows as occurring when injecting the steel reinforcement are eliminated because the textiles are gently pressed in the fine injection mortar. The load-bearing capacity and serviceability of reinforced concrete components can be enhanced significantly by means of thin textile-reinforced concrete layers.

Ellipsoid with shotcrete shell

The actuality of concrete shells was demonstrated on the distinctive dome of the shopping center in Chiasso. This building component allows great spans at a concrete thickness of just a few centimeters thanks to its double curvature. The up to 22 m high concrete shell of the shopping center in Chiasso is shaped as an ellipsoid that is up to 93 m long and up to 52 m wide with a wall thickness in the range of 10 to 12 cm made of reinforced shotcrete on timber formwork. Concrete shells are a competitive and efficient solution, also allowing the successful realization of architectural masterpieces due to their flexibility.

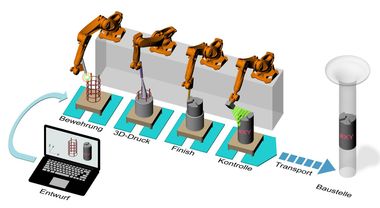

From time to time, the construction industry suffers from the fact that innovations penetrate the market relatively slowly. With Nest, a research project of ETH Zurich and Lausanne as well as the Swiss Federal Laboratories for Materials Science and Technology (EMPA), a future laboratory is being built at present for research and transfer of technology in the construction sector. This is a kind of „upside down“ laboratory where research takes place outside instead of inside. A core with cantilevered slabs serves as the basic infrastructure for the stories covering 600 m² and being connected by cable shafts. The stories will be furnished as living and office spaces used by the EMPA. For gaining as much experience as possible, single components of these spaces will be rebuilt or entire facilities will be dismantled and replaced by new generations periodically and in a subject-related way. Thus, Nest becomes a constantly changing building where the practical suitability of new concepts can be tested again and again under real-life conditions. This includes, among others, the building envelop, convenience, energy, water consumption, automation and new materials.