PCE-based superplasticizers for composite cements

containing calcined clay

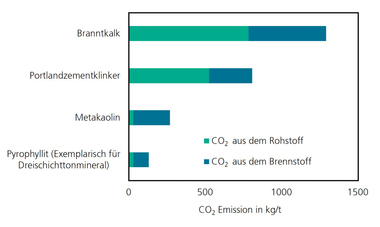

Global cement production currently amounts to about 4.4 billion tons per year. Unfortunately, this comes with a huge CO2 emission which represents approximately 7 % of total anthropogenic CO2 output. A major source (~ 60 %) of the CO2 emission in cement manufacture is the decarbonation of limestone. Hence, a more eco-friendly binder is required.

Thermally activated (calcined) clays (CCs) have been identified as a very promising approach to reducing the clinker factor in cement and to reducing its CO2 footprint. A typical example of such an eco-friendly binder is LC3, which contains 50 % clinker, 30 % CC, 15% limestone powder and 5 % gypsum.

The problem of using calcined clays lies in the huge variation of natural deposits with respect to their clay composition. Depending on the type of clay, different calcination temperatures are required. Moreover, CCs containing high amounts of calcined kaolin (metakaolin) are favorable with respect to early strength development, but significantly increase the water demand which necessitates the addition of dispersing polymers (superplasticizers) to such cements. On the other hand, meta illites and smectites do not impact the water demand much, but they provide relatively poor early strength which prompts the need for hydration accelerators.

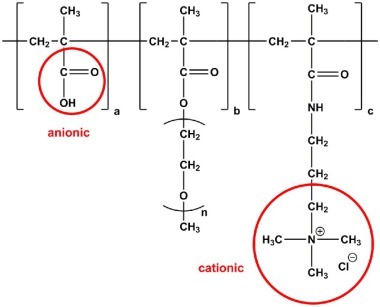

This paper highlights the progress made so far with respect to the problems mentioned above and addresses potential solutions based on specifically designed polycarboxylate comb polymers. Their chemistry, molecular properties, and physico-chemical interaction with cement and CC will be presented.

It is concluded that calcined clays of broad variation relative to their composition can be used successfully in blends with Portland cement clinker, provided that they are applied in combination with superplasticizers tailored to their specific surface chemistry. This way, in cement production potential savings of approx. 1 to 1.3 billion tons of CO2 seem to be achievable, thus making cement “greener”.