Innovative superplasticizers for thermally activated (calcined) clays

The use of thermally activated (calcined) clays as supplementary cementitious materials (SCMs) in cement represents a promising optimization step for ordinary Portland cement in terms of environmental impact and energy efficiency.

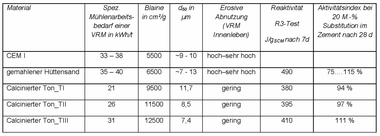

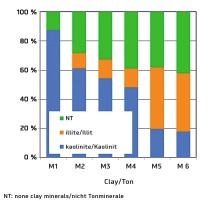

Calcined clays are produced by large-scale calcination of naturally occurring, abundant clay minerals. They contain various phyllosilicates such as kaolinite, illite, and mica, as well as a wide range of inert minerals including silica, feldspar, sulfates, and carbonates. These clinker-reducing materials can decrease the workability of cementitious mixtures. Consequently, superplasticizers have to be added to improve fluidity. The big challenge in the development of new superplasticizer structures for those binders is to reduce the relatively high water demand of certain calcined clays whilst ensuring effective interaction with the diverse, mosaic-type surface charges of both cement hydrates and clay minerals.

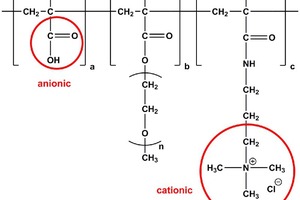

It is well-known that currently used polycarboxylate-based superplasticizers (PCEs) work via surface adsorption on the binder system. With a view to the heterogeneous surface charge characteristics of cements containing calcined clays, the focus is increasingly shifting to amphoteric (zwitterionic) superplasticizers.

Incorporating cationic (quaternary ammonium) functional groups into the originally anionic structure of common PCEs generates polymers with cationic and anionic charges in a single molecule (= zwitterionic) (Fig.). By using such novel, modified PCEs, it is possible to adapt the superplasticizer to the huge variety of ion layers on clayey mineral surfaces as well as on cement hydrates.

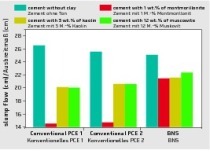

Studies of the interaction of these amphoteric polymers with pure calcined clays as well as with cements with calcined clay substitution rates between 20-30 % by mass showed an optimized dispersing effect similar to that of common PCEs.

In summary, the design of novel superplasticizers for such blended cements constitutes a wide field for future research. This applies particularly to the specific demand for tailored dispersants that work with various calcined clay mixes whose surface chemistry can differ greatly.