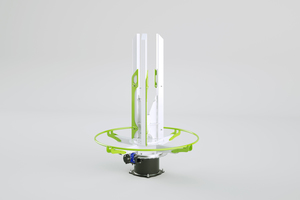

Perfectly uncoiled – innovative wire coil system

“Wire uncoilers or reels have been among the most problematic challenges in the industry for years. We had long been tinkering over this problem until we were able to permanently eliminate the many challenges involving this issue,” says Hubert Rappers-torfer, owner and managing director of Rapperstorfer Automation, based in Steinhaus, Austria. This seemingly simple component of many production systems is, indeed, a well-known trouble spot. The wire unreeling system from the coil can stop the entire production process or be the beginning of perfect workflow. For the past 35 years, much has been tried and tested in this area. We have taken an entirely new approach and are convinced that we have come a major step nearer to squaring the circle,” says Rapperstorfer.

Until now, the wire coils had been simply positioned on a plate. A straightening machine pulled the wire down and manufacturers tried to balance the installation of a variety of motors with coiling and straightening machines. Rapperstorfer and his team were not satisfied with this solution. Because, no matter which automatic system it was based on, perfect synchronization of coil and straightening system always failed to succeed. Due to the fluctuating diameter at the coil, either too much or too little wire got unwound.

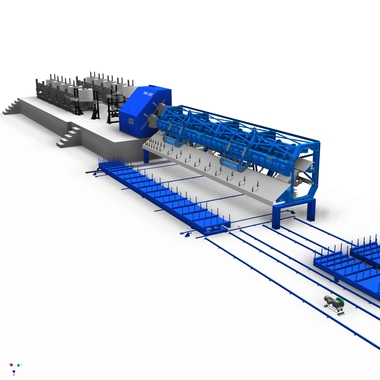

The engineering team at Rapperstorfer Automation took a step backward in technology by completely eliminating the drive of the reel. “Instead, we developed an extraction system that exactly uncoils the wire lengths required for the straightening section,” explains Rapperstorfer. The differences in speed are compensated for by a wire bearing. In this manner, both the wire straightening procedure and the unreeling system can work continuously at ideal speeds. The Mia rotary straightening machine, likewise from Rapperstorfer Automation, has in this way been given a counterpart that stands on absolutely equal technological footing.