Pioneer of BIM-supported precast production in Finland

Lujabetoni is one of the major manufacturers of structural precast elements in Scandinavia. The company, located in Siilinjärvi near Kuopio in Central Finland, has since the 1990 s closely cooperated with Tekla Corporation (Espoo), one of the key pioneers of D (BIM) modeling.

More than 30 representatives of Fib and Cerib made their way from France to the Hämeenlinna plant, located about 70 km of the capital of Helsinki, to obtain a convincing, first-hand impression of the high standard of structural precast element production in Finland. And they were not disappointed. Lujabetoni has been one of the pioneers of 3D (BIM) modeling and IT-supported precast production since the 1990 s.

The beginning of cooperation with the software company Espoo in southern Finland in 2005 was a crucial milestone. Today, all large-scale projects are carried out at Lujabetoni jointly with Tekla – from the initial phase of quotation to final, post-completion costing. Two recent major contracts alone, according to the company, have amounted to 80 % of total annual turnover in 2014.

Three million railroad sleepers already supplied

In railroad sleeper production, the company is leading in Finland – it has by now supplied an impressive 3 million sleepers with spans of up to 3.80 m. Lujabeton is also among the market leaders for structural precast elements in buildings: e.g., beams, columns, floor slabs, and façade elements. The company also supplies landscaping products, modular blocks, and a wide range of concrete products for agriculture. Ready-mixed concrete production, primarily for local customers, is another major area of business.

The Hämeenlinna-Kantola plant was opened in 1994. With a workforce of 80 in two-shift operations, this plant alone generates annual sales of 8 million euros. Total sales realized in all its precast plants, with a total workforce of 626, has most recently amounted to 135 million euros. The entire Luja Group employs a workforce of 1,437 in 43 plants in 31 cities. The company delivers most of its precast parts to the domestic Finnish market. In addition, companies in the metropolitan areas of Stockholm and St. Petersburg are customers of Lujabetoni, which in Sweden and Russia – with L Betong AB and OOO Lujabeton – operates its own subsidiaries.

Kari Turunen, Vice President of the Luja Precast Division, tells his guests not without pride that among others, approx. 8,000 m³ frame elements, 100,000 m² hollowcore floor slabs, and 5,000 concrete pipes left the Lujabetoni plant last year. Output also included a considerable volume of ready-mixed concrete. Plant engineering, raw materials, and the required equipment accessories are obtained mainly from the Finnish manufacturers Elematic, Scandinavian/Northern Cement, and Peikko. Peikkko manufactures the required connection and anchoring components in Lahti – e.g., all of the column shoes for the precast Lujabetoni elements.

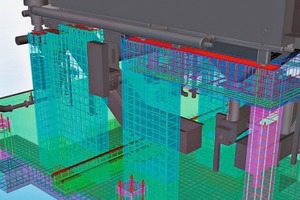

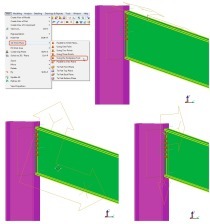

Added value from the Tekla Warehouse online library

“For us, we can no longer imagine precast production nowadays without BIM,” said Kari Turunen in praise of satisfactory collaboration with Tekla over many years. “We are proud to be among project partners of Tekla who have represented the pioneers of building information modelling (BIM). According to Toni Kamula, Marketing Manager at Tekla, the new Tekla online library particularly offers considerable added value for manufacturers. ”Although it was previously a relatively complex process, following the actual BIM main planning, to choose, for example, the required accessory equipment, it is now possible to select the appropriate products of the various suppliers from a modular system – virtually by mouse click.”

A member of the French delegation of visitors added: “Although France has been among the leading industrial and technological nations worldwide, we wish that our concrete manufacturers would make even more systematic use of these newly opened possibilities.”