Planning assurance in the face of new challenges

Controlled concrete curing relies on specific moisture and temperature within the process environment that is conducive to the process. By controlling and influencing these factors in the early stages of concrete curing, different, precisely defined properties of the concrete can be achieved, making the applications of this building material even more diverse.

What counts here is not only quick delivery, but above all quality, so that today‘s customer is also satisfied in the long term. The desire is to create a product that does not cost much, can be delivered at short notice, and in addition has uniform colors, no efflorescence, and flawless edges and corners. To ensure these properties, among many factors, controlled concrete curing must be applied.

Successful reference project

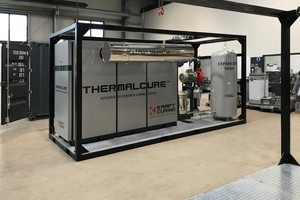

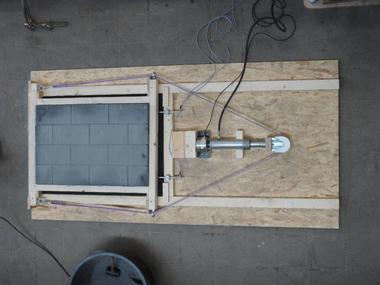

The Kraft Curing team quickly rolled up their sleeves after receiving this rush order from the USA for a 94% efficient 1,400 kWh ThermalCure hydronic heating system for the accelerated curing of 2 each 80 m and 1 each 65 m prestressed concrete beds with reserve capacity for future production capacity expansion. The design, fabrication and testing of the be-spoke palletized heating unit, AutoCure controls and the complete 100°C heat pipe distribution system, including 600 m of insulated supply and return pipe was completed within 6 weeks from date of order. 2,700 m of ribbed pipe for installation under the beds is supplied from the USA.

Actually, quick turn-around projects with ultra-short deadlines are becoming more the rule than the exception for Kraft Curing Systems GmbH. In perfect harmony, the engineering department and workshop mastered this challenge by prioritizing long lead components, fabrication drawings and manufacturing so that the project was being fabricated before all drawings were completed. Precision work during the planning and production of the piping, and especially during loading into the sea container – with only centimeters to spare, demanded the full attention of all departments. On-site activity will require similarly precise timing and coordination in order to complete the project and be operational per the client’s fast-track schedule.

CONTACT:

Kraft Curing Systems GmbH

Muehlenberg 2

49699 Lindern/Germany

+49 5957 96120