Plant modernization with high-performance turbine mixer THT

Having been specialist in plant modernization and conversion for decades, Teka Maschienbau GmbH based in Edenkoben in the German region of Palatinate can draw on a wealth of knowledge and experience. Long-term and very experienced staff members provide the customers with intensive advice regarding the respective individual projects. Hence, every project is analyzed and planned individually for finding an optimum solution together with and for the plant operator.

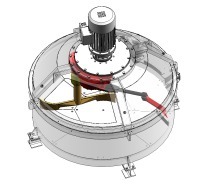

For several years now, the company has been successful in plant modernizations with the Teka high-performance turbine mixer, which was presented at Bauma 2013 for the first time. Teka mixers have meanwhile established themselves in many concrete plants manufacturing high-quality products. The turbine mixer THT is predominantly used for difficult mixing tasks such as face mix concrete, colored concrete, fiber-reinforced concrete, and polymer concrete as well as self-compacting concrete, with achieving excellent mixing results at any filling quantity - even in case of the absolute smallest batch sizes. The new THT series has also successfully proven for refractory materials and drywall construction materials.

Slab production plant at Feiner modernized

For this reason, Teka Maschinenbau GmbH was awarded a contract for the complex modernization of the renowned slab production plant at Feiner located in Furth im Wald, hence including planning, delivery, installation, and commission of the modernized plant. A crucial criterion for the decision was the performance of the new Teka high-performance turbine mixer, for example, the enormous variability of mixing batch sizes and the resulting potential for manufacturing a quite wide variety of products. The contract comprised a turbine mixer of type C-1-II with an output of 0.25 m³ per batch and a turbine mixer of type D-1-III with an output of 0.33 m³ per batch for feeding the slab press.

The mixers are configured in accordance with the specific requirements of the individual customer in combination with the components required correspondingly, and not according to the maximum filling capacity of the mixer, as usual. Every single mixer can be perfectly configured according to the respective products to be mixed.

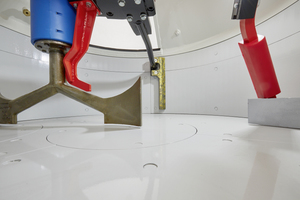

The Teka turbine mixer with frequency-controlled drive is distinguished by an intensive mixing action in a very short time, while the turbine mixer is achieving excellent mixing results even in case of the absolute smallest batch sizes.

Fields of application of the turbine mixer

The Teka turbine mixer is predominantly used for special concrete types and at concrete manufacturers, respectively, where many different products of high quality are produced, requiring frequent product changeovers which include frequent color changes. In addition to this, for concrete types using aggregates with high fine particle content, such as face mix concretes and self-compacting concretes. The Teka turbine mixer can moreover demonstrate its strengths when it comes to mixing small batch sizes or even the smallest batch sizes. Even minimal quantities of less than 10 % of the maximum filling capacity of the mixer can be perfectly mixed in practice.

In the meantime, the turbine mixer has stand the test in practice at lot of renowned manufacturers of concrete products as well as for many different and difficult concrete types. In general, the Teka high-performance turbine mixer is ideally suited for the most difficult mixing tasks and various batch sizes. In this way, the operator is generally in the position to manufacture a wide variety of concrete products.

Manufacturers of concrete products have the opportunity to carry out mixing tests at the internal testing facility at the Teka factory in Edenkoben and thus convince themselves of the turbine mixer personally. Teka has already realized plant modernizations using high-performance turbine mixers at many concrete plants with success. The satisfaction of the customer and the successful implementation of the plant modernization has always top priority for the supplier.