Innovative Teka mixing technology for concrete plant modernization at A2C Préfa in France

It was only recently that A2C Préfa, a leading French precast concrete producer, has modernized the production technology at its Sivry-Courtry factory. Above all, Teka France played a leading role, supplying a Teka THT 3000 (type K-3-VII) high-performance turbine mixer with a frequency-controlled 90kW drive motor and a maximum concrete output of 2.0 m³ per mixing batch.

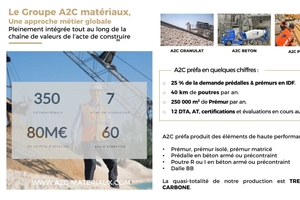

As a market leader in the field of prefabrication of construction systems made of concrete in the metropolitan area of Paris, A2C Préfa is developing new projects as a conscientious company and offers high-performance and environmentally friendly technical solutions in order to meet the challenges of the energy and environmental transition. Other companies of the A2C Matériaux Group are A2C Granulat and A2C Béton.

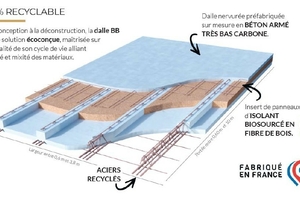

So as to achieve its goals in terms of sustainability, A2C Préfa decided to modernize its production plant. In this regard, they spent much planning work in waste recycling, in reducing pollutant emissions, in water treatment and in the further development and production of innovative concrete products. The main product of A2C Préfa is the BB floor slab, a completely new combination of wood and precast concrete floor slab.

A2C has modernized its production technology only recently. In addition to the Progress Group (see article in BFT 09/2023), Teka Maschinenbau GmbH above all played a leading role here.

From the beginning in the 1960s until today

Jacques Charle developed the company that his father André had acquired in 1961. They started with sales of gravel required for the expansion of southern road structures in Seine-et-Marne. Back then, the yard was situated in the alluvial plain of La Bassée in Saint-Sauveur-lès-Bray and had a workforce of three people. In the course of time and technological progress, investments were more and more aligned to the market. The sales volume was rising fast and amounted to 250,000 tons in 1968.

The overall production reached a record high in 2006 amounting to 1,100,000 tons. The factories in Corbeil and Sivry ran at full capacity, producing 30,000 m of beams and 550,000 m² of floor slabs. In December of the same year, Sablières de Saint-Sauveur-lès-Bray, Sablières du Nogentais, Corbeil Prédal and Sotécoba merged to become the A2C Matériaux Group.

Despite a new general crisis, the company invested in the 2010s into a new plant for the extraction of limestone from Champigny to Pécy and after this into a high-tech industrial unit with the production facility in Sivry.

Today, the energy transition is in full swing; A2C is proud on its past and is looking into the future with determination. The company is developing innovations with low-carbon materials to respond to these challenges and brings, among other things, the above-mentioned BB slab (wood-concrete) with carbon savings of 47% to the market. This slab is based on a ribbed floor slab made of low-carbon steel-reinforced concrete, where the spacings are filled with a wood-fiber insulation of type Pavawall GF made by Soprema.

High-performance and certified products

In 2022, about 350 employees generated a revenue of 80 million Euros. The high-performance and certified products are integrated in construction specifications of offices, commercial areas, residential buildings and large public facilities. With two separate production sites in the Ile-de-France region (Corbeil and Sivry-Courtry), the activities of A2C Préfa respond to both the quantity-related needs and the quality requirements of the customers.

A2C runs an efficient planning office and provides a wide range of products and services in line with to the requirements of construction sites and has a large production capacity. Sébastien Straub, Directeur Industrial at A2C Préfa, reported: „At two production sites, we manufacture approx. 350,000 m² of precast slabs, 100,000 m² of BB panels, 250,000 m² of wall elements and 40,000 m of linear precast concrete elements such as columns, beams and purlins. With this huge performance, we are in the position to realize up to 180 projects simultaneously.“

A2C Matériaux – the right material in the right place

From the extraction to recycling of aggregates through to the production of prefabricated high-performance construction systems – the A2C Matériaux Group is innovative and is investing to fulfil the expectations and needs of the players in the construction industry correspondingly. The company always cares for the environment and implements at all of its locations solutions that combine performance, efficiency, the reduction of the carbon footprint and environmental protection. This virtuous approach that has been pursued for many years becomes an absolute necessity given the continuous development of regulations and the climate emergency, we are all facing.

In order to respond to these global challenges, A2C relies on three strategic strengths:

1) Precast building solutions free of carbon, incorporating bio-based elements into the shell construction directly – i.e. with short distances, with circular economy and off-site production that assure an increase in health, safety at work, quality of life and the quality at work.

2) Concrete aggregates coming from different kinds of deposits (limestone and alluvial land) and that together allow for a restriction of the clinker content in cement. The extraction and production of these aggregates take place close to the job site, using industrial processes consuming low amounts of fossil energy.

3) Solutions in the proximity allowing for the reclamation of excavation areas on construction sites in the metropolitan region of Paris as part of the restoration of own quarries with ecological and agronomic benefits, providing services for the ecosystem – as most important examples to be mentioned in this regard are the restoration of flood plains in La Bassée, creating biodiversity and helping to protect the water resources of La Bassée, as they replace unproductive agricultural areas being prone to flood and dryness, or the restoration of agricultural zones in the region of Brie, which are supplemented by denitrification systems of water catchment areas and accompanied by natural areas of high ecological potential, deviating from the original habitats.

The wood-concrete floor slab (BB) – an ecologically conceived construction system

The commitment of the A2C Matériaux Group is based on the two fundamental principles of diversity (because the right material is used in the right place) and economy, because materials or natural resources are only used in those places where it is necessary.

The wood-concrete (BB) floor slab was designed because of these commitments and these principles. Using the BB floor slab, an average of 60 % of greenhouse gas emissions per m² floor space are avoided in comparison to conventional concrete solutions. This also means that more than 50 % of concrete in the finished floor and slab, respectively, are replaced by wood fibers from waste of the wood industry.

Production Manager, Sébastien Straub explains: „The BB floor slab is also a guarantee for ‚change without changing‘! Change because the impact on the environment is reduced and new legal requirements can be met, however, without changing the construction method or the properties of concrete. Acoustics, fire resistance, thermal or structural properties are not impaired. The BB floor slab is the outcome of a long innovation process. In fact, more than eight years of development work, hundreds of tests, two patents, a technical expert assessment and a new production hall.“

Eventually, the BB floor slab is a 100% recyclable solution. It was conceived along its entire life cycle in order to ensure the modularity of the buildings, in particular, by the incorporation of sanitary and electrical installation at the factory. The slab can be dismantled and fully recycled – not mixing the materials. A2C has built a new production unit for manufacturing this main product – the BB floor slab. Right in the center of the Progress circulation plant, A2C has installed the concrete mixing plant in cooperation with the Fameto company.

The development of the BB floor slab is a constant process and A2C has realized several important projects in the region of Ile-de-France, but also in the region of Bordeaux. The total investment is amounting to approx. 17 million Euros. The production plant will be able to produce 500,000 m² of BB floor slabs and steel-reinforced concrete elements per year.

Innovative Teka mixing technology for A2C Préfa

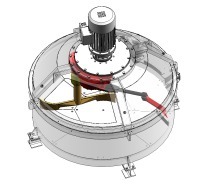

„The high-performance THT 3000 Teka turbine mixer (type K-3-VII), supplied by Teka France including a frequency-controlled 90 kW drive motor and a maximum concrete output of 2.0m³ per batch, is the ideal mixer for the innovative production of environmentally-friendly floor slabs that are produced with recycled wood,“ states Stéphane Sciquot, Branch Manager at Teka France.

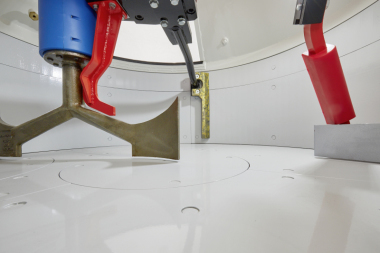

This THT 3000 high-performance turbine mixer with cutting-edge mixing technology is fitted with a patented mixing turbine, a fast rotating mixing star as well as a counter-rotating mixing star, ensuring very intensive mixing of the batch, while leaving the aggregate particles intact and thus not altering the grading curve. The counter-rotating mixing principle means that the turbine mixer is a real counterflow mixer. One mixing star is rotating to the left and the other mixing star as well as the also rotating discharge paddles and wall scrapers are rotating to the right, while they are continuously feeding material to the patented mixing turbine. This means a very intensive and quick thorough mixing of the material in a very short time, a very high degree of homogenization and an optimum distribution of the mixing water with a straight moisture curve shown in moisture measurement.

Furthermore, the two mixing stars and the mixing turbine are rotating in different effective radii so that the pan bottom is covered several times, ensuring an optimum mixing action. In addition to that, the patented mixing turbine is equipped with a scraper with self-cleaning effect. The mixing turbine is coated with tungsten carbide to ensure a long service life.

This THT 3000 turbine mixer, equipped with a high-pressure cleaning system, has a special extra sealing in the mixer cover, in the lifting segments as well as in the inspection flap so as to avoid water discharge. Moreover, the mixer was fitted with a smaller special discharge unit to drain the waste water precisely. At A2C, the turbine mixer was complemented with a Teka special charging unit as skip hoist with two independent rope winches and a skip hoist inclination of 70° with rope monitoring as an option. This special rope monitoring system of Teka identifies a potential rope breakage at an early stage by sending a signal to the control system. This feeder in a customized design had to be fitted into the existing steel structure and was designed and manufactured especially for the conversion accordingly. One of the main advantages in comparison to other mixer types is the possibility of mixing even smallest batch sizes or small batch sizes for special products. This is where the turbine mixer shows its peak performance.

Since the introduction of the new Teka high-performance turbine mixer with patented mixing turbine, the Teka turbine mixer has been operating with success at a great number of well-known concrete plants in Europe. The THT turbine mixer has since stand the test several hundred times and is predominantly used for high-quality concrete products and/or difficult mixing tasks such as face mix concrete, colored concrete, fiber-reinforced concrete, and polymer concrete as well as self-compacting and ultra-high strength concretes, with achieving excellent mixing results at any filling quantity (even if the absolute smallest batches are concerned). The new THT series has also successfully proven itself for refractory materials and drywall construction materials.

The Teka turbine mixer is primarily used for the following special concretes and/or concrete manufacturers:

at producers which manufacturer many different, high-quality and innovative products, requiring many product changeovers, including frequent color changes;

for concrete types with a very high ratio of ultra-fine aggregate particles, such as face mix concretes and self-compacting concretes, etc.

at producers which have to process minimum batch sizes or absolutely small quantities.

In practice, even batch sizes of less than 10% of the maximum filling capacity can be mixed for customized products. The mixers can be configured in accordance with the specific requirements of the individual customer in combination with the components required correspondingly, and not according to the maximum filling capacity of the mixer, as usual. Every single mixer, as in case of A2C, can be perfectly configured according to the respective products to be mixed.

The statement of Sébastien Straub was positive in this respect too: „As mixer we selected a THT of Teka which we have equipped with a number of options. We have developed an internal lighting system for the mixer so that opening of the two discharge gates is avoid for cleaning purposes. The outcome is convincing; there is no longer splashing outside and the cleaning time could be reduced. Thanks to this equipment, we are geared up for continuing our concrete developments with confidence.

The characteristics of the new turbine mixer series can be summarized as followed:

Guarantee of an enormous product variety by the operator

The patented mixing turbine ensures a very wide variety of products, among others, providing the option of processing quite different mix designs, batch sizes and even the smallest batch sizes in a single mixer. Thus, even minimal quantities of less than 10 % of the maximum filling capacity of the mixer were perfectly mixed in practice, even with very demanding concrete mix designs.

The patented mixing turbine ensures complete emptying within extremely short times for product changeover purposes, as well as an extremely short mixer discharge process.

Furthermore, the mixing cycle in respect of mixing and discharge times could be reduced. Hence, discharge times of less than 50% of a conventional planetary mixer are no exception. Another decisive advantage is the interaction between the mixing turbine and the discharge scraper, which ensures an exceptionally fast complete emptying.

Most intensive mixing for special and high-performance concretes

The patented mixing turbine and the „swing and throw effect“ ensure optimum mixing action even in case of the most difficult special concrete grades and high-performance concretes.

A virtually straight moisture curve shown in moisture measurement and optimum distribution of the mixing water correspondingly.

No aggregate particle destruction and thus leaving the grading curve undisturbed.

Very low operation and maintenance costs

There is a very low wear and tear in comparison to other mixer types owing to the special shape of the mixing turbine as well as the low number of mixing tools. Moreover, it is possible to provide the mixing turbine with a tungsten carbide protection. The very low number of mixing tools also ensures very low cleaning costs and long cleaning intervals with minimum cleaning times, respectively; this is added by an own scraper for the mixing turbine.

Practice has proven that contamination and cleaning costs can be reduced to a minimum, among others, due to the scraper attached to the mixing turbine. These benefits are immensely important when it comes to frequent product and color changeovers. The low wear and the associated low costs as well as the limited amount of required cleaning result in low maintenance and servicing costs. The mixing turbine is also adjustable in height without any problems, allowing the turbine to be ideally set to the pan bottom, minimizing wear and tear and ensuring very fast and clean complete emptying of residues.

Energy efficiency

The motor output is perfectly aligned with the batch to be mixed as well as the specific mixing task. Different motor and gear versions are available for the same mixing chamber size. In this way, the motor outputs are utilized perfectly, resulting in a correspondingly high energy efficiency.

In the meantime, the Teka turbine mixer has stand the test in practice at lot of renowned European manufacturers of concrete products as well as for most different and most difficult concrete types. With the aid of a Teka testing station, concrete producers can run mixing tests at their own concrete plants and with their materials, thus convincing themselves of the turbine mixer personally.

Teka Maschinenbau GmbH is one of the leading suppliers of high-performance mixers as well the conversion and modernization of plants for the concrete product and precast concrete industry. In the last few years, a large number of concrete plants were modernized to meet the recent requirements of the customers. This is always focused on the satisfaction of the customers and a successful realization of the plant modernization.

From the cooperative preliminary planning with the customer to project design, assembly and commissioning, Teka Maschinenbau GmbH as well as the subsidiary, Teka France located in Weißenburg/Alsace, offer the full range of products and services from a single source. Like the parent company based in Edenkoben, Teka France provides a highly efficient customer service as well as an extensive spare part warehouse so as to offer top-class service to the French customers.

Impressive reference projects

Stade de France, the Cœur Défense and T1 towers, Hôpital Sud Francilien, S3 und S4 satellites at the Roissy Charles de Gaulle airport are among the most impressive projects with products made by A2C during the last few years. The company is proud, for example, on the contribution made to the Olympic Games 2024 in the French capital city and in the metropolitan area of Paris. In summer of 2022, the BB floor slabs were delivered for the Wood‘up Tower (Paris Bercy) that will become the tallest tower in Europe with 17 stories in a timber frame design.

CONTACT

A2C Préfa

RD 605 – ZA La Meule

77115 Sivry-Courtry/France

+33 0160 689900

www.a2c-materiaux.com/a2c-prefa

Teka Maschinenbau GmbH

In den Seewiesen

67480 Edenkoben/Germany

+49 6323 809-0